Manifolds Installation guide

All tubing and plumbing connections located at the manifolds are required to be installed by a licensed plumber or radiant heating contractor.

Before proceeding, carefully evaluate and tighten all fittings on the manifold to prepare the manifolds for installation. DO NOT use manifolds, fittings or repair couplers that are not supplied by Warmboard.

Minimum Framing Dimensions

Installation Instructions

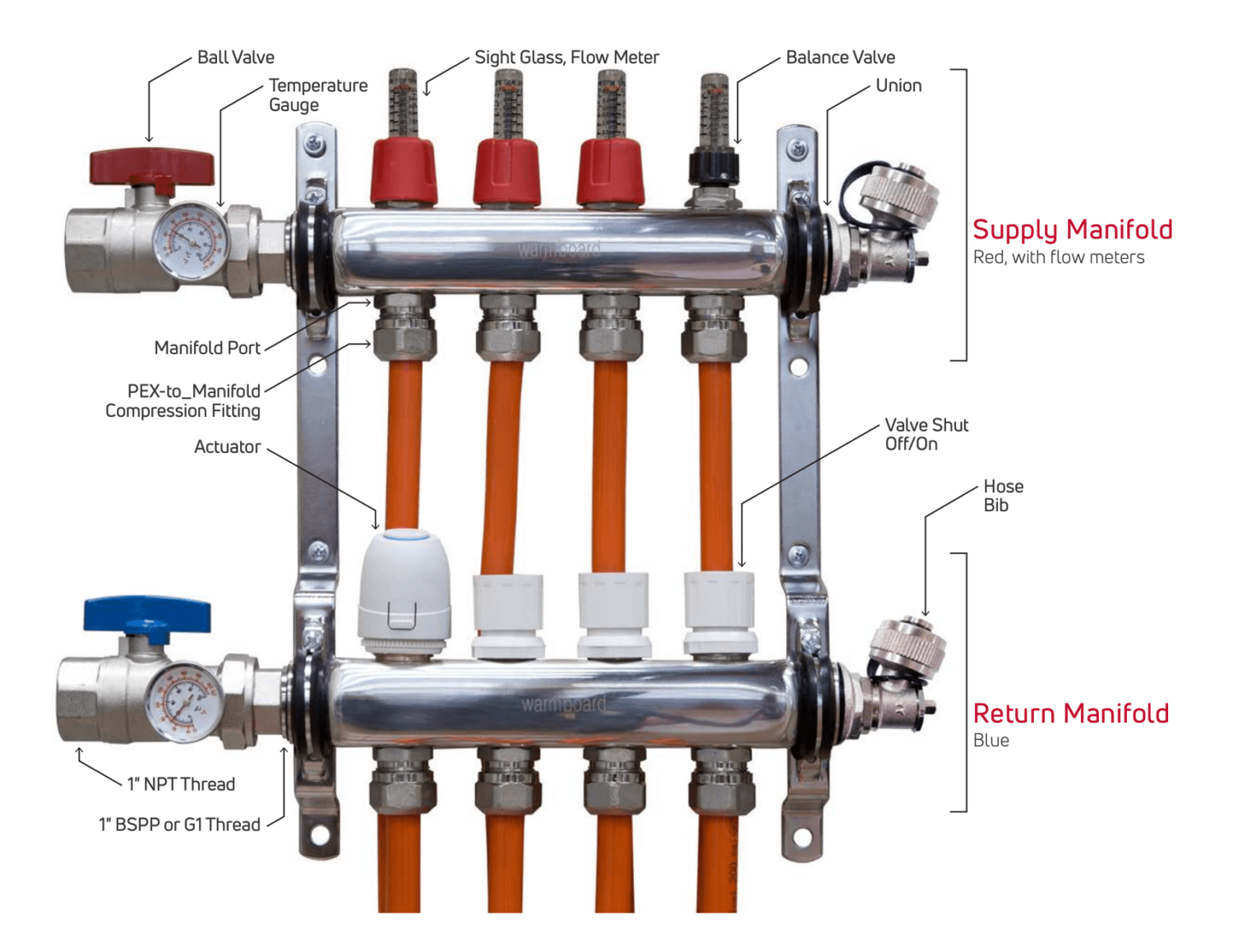

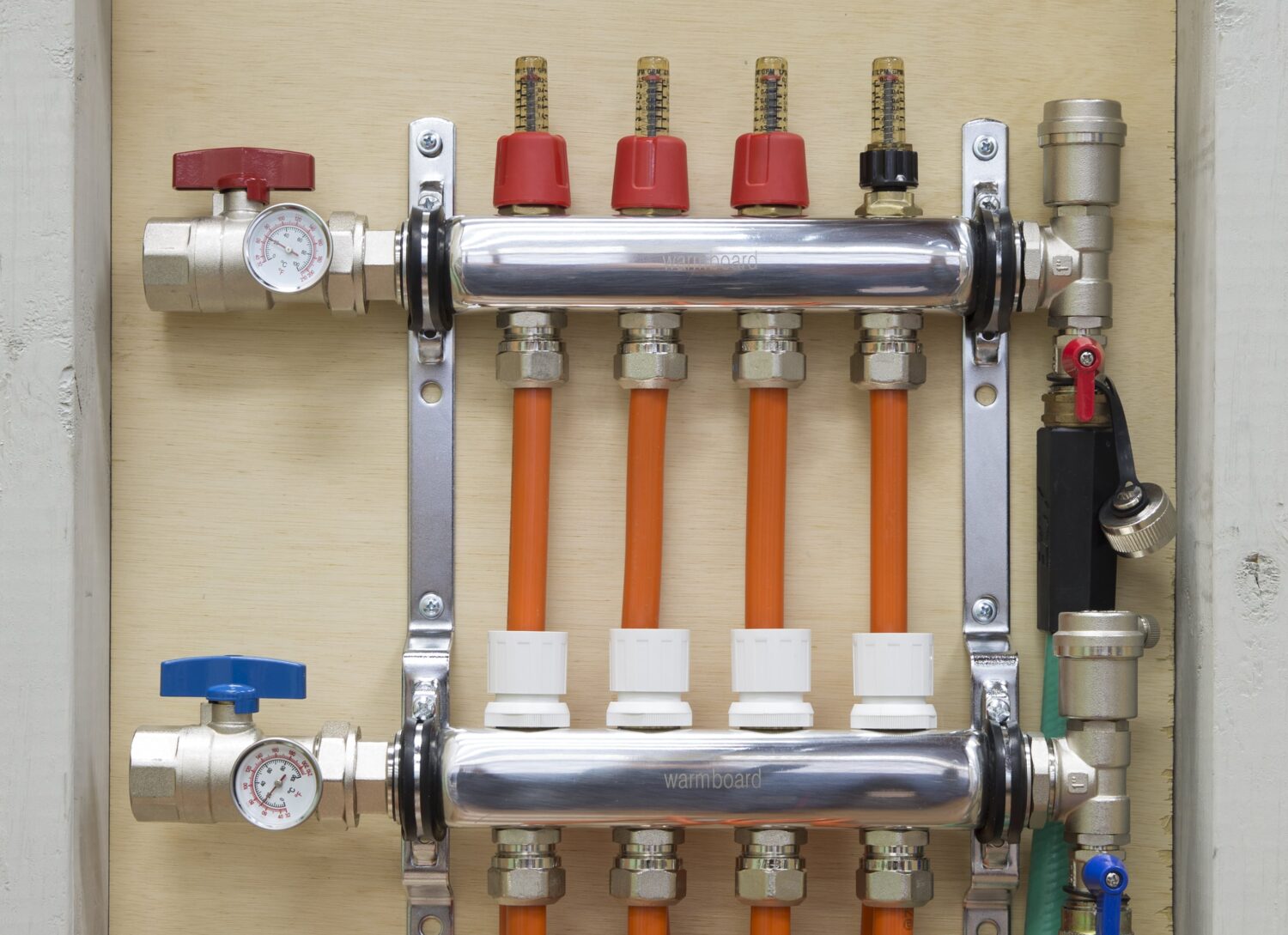

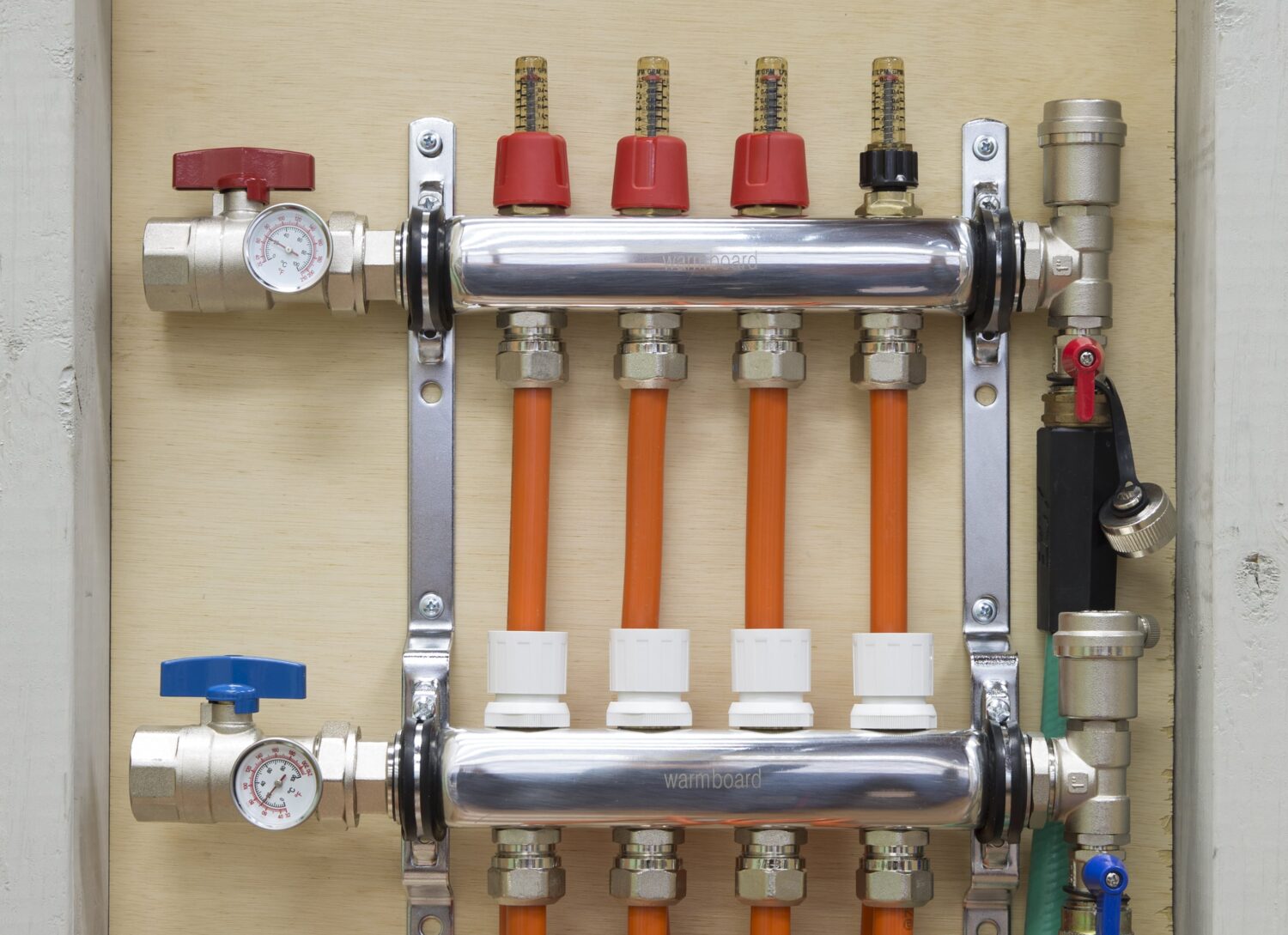

Assembly the manifolds by attaching the red parts to the Supply (top), and the blue parts to the Return (bottom) – DO NOT reverse these

Warmboard branded manifolds can be installed with the tubing ports facing downward (most common), upward or sideways. Choose a position that works best for your project. If using a different brand, check with the manufacturer for their preferred method

Install in a 2″ x 4″ wall (2″ x 6″ or greater preferred). If unable to meet the minimum framing dimensions (chart), furring out the framing with studs in a closet is an excellent option

To fasten the manifolds with factory brackets, cut a piece of 1/2″ plywood 20″ long and the full width of the manifold studs. DO NOT use plywood thicker than 1/2″ as this will force the manifold to protrude beyond the sheet rock (photo)

Install the plywood with “L” brackets and 1/2″ wood screws, then install the manifolds with same screws (photo)

The manifolds MUST be accessible. Finish the installation with a simple cabinet wood door that mounts over the sheet rock

The failure to use a properly licensed installer, failure to use the required parts and components and/or any deviation from these installation guidelines will void any product warranty

Tubing-to-Manifold Connections

Mandatory Notes

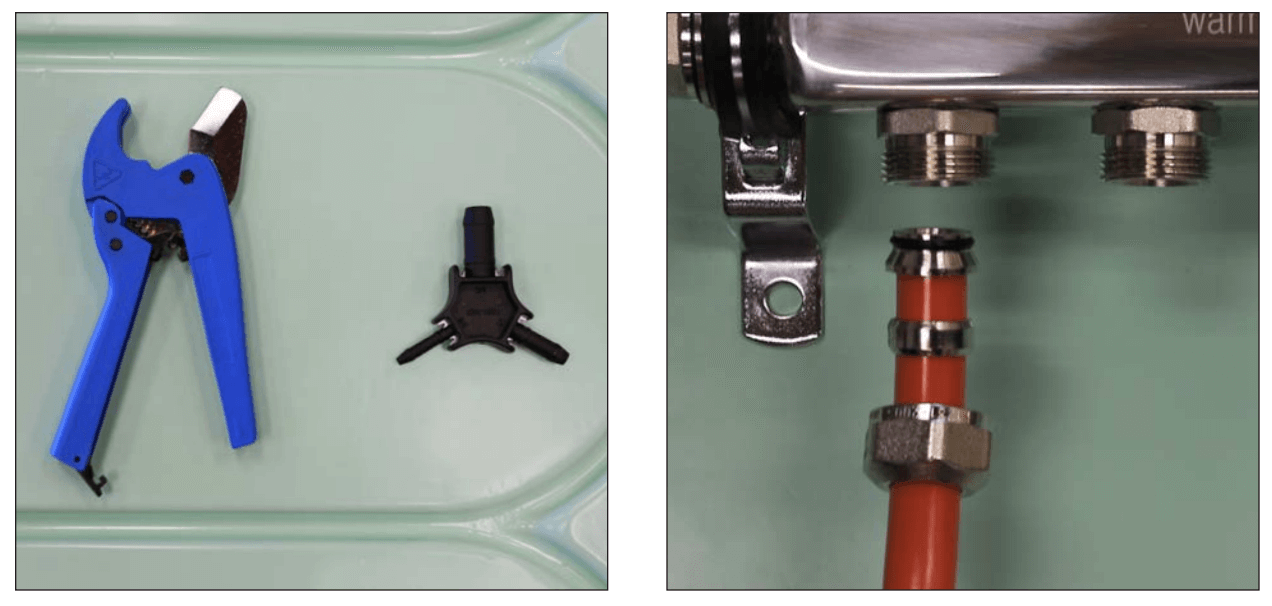

- All PEX tubing cuts should be straight and square and made with a proper PVC cutter

- Use the chamfering tool on all PEX tubing connections before a fitting is installed

- Insert the chamfering tool completely into the tube until it bottoms out, then spin the tool to cut a beveled edge into the tubing

- Mark all PEX connections at the manifold to clearly communicate the loop number and zone for each area being heated (Tubing Design Document)

- To connect the PEX tubing to the manifold, use the compression fitting (nut, ring and insert) shown

- DO NOT tape, dope or overtighten – fasten snugly

Review the Warmboard-S or Warmboard-R Installation Guide for more information on tubing installation.

Pressure Testing

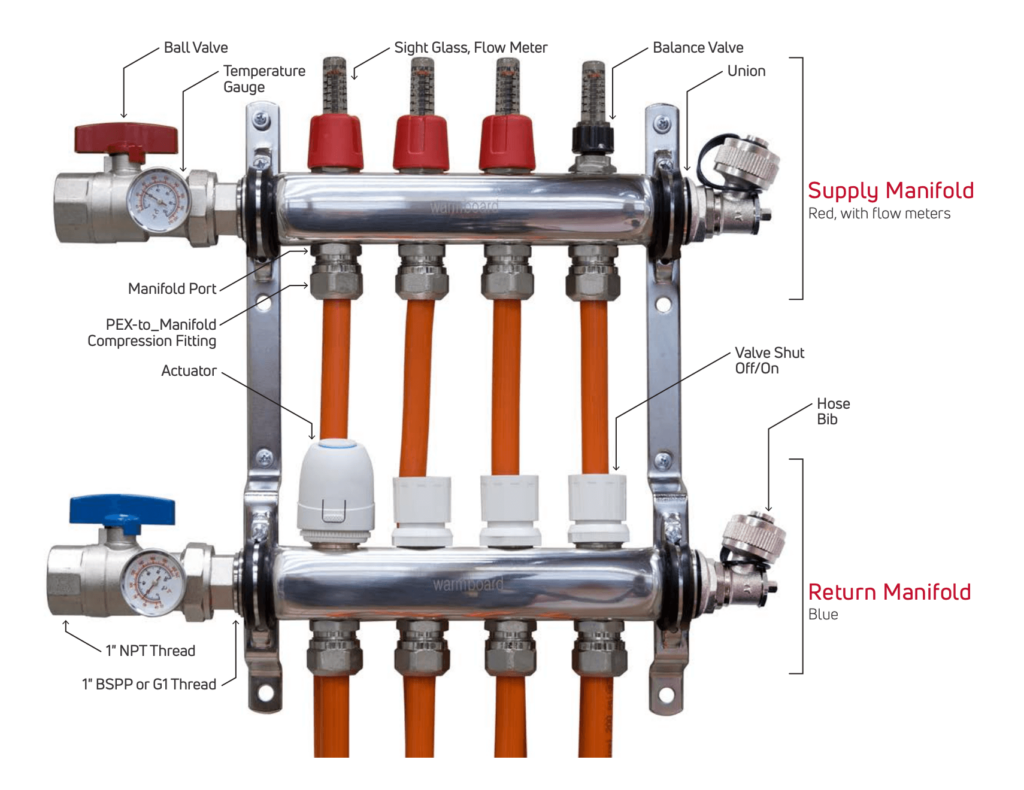

Using the test kit

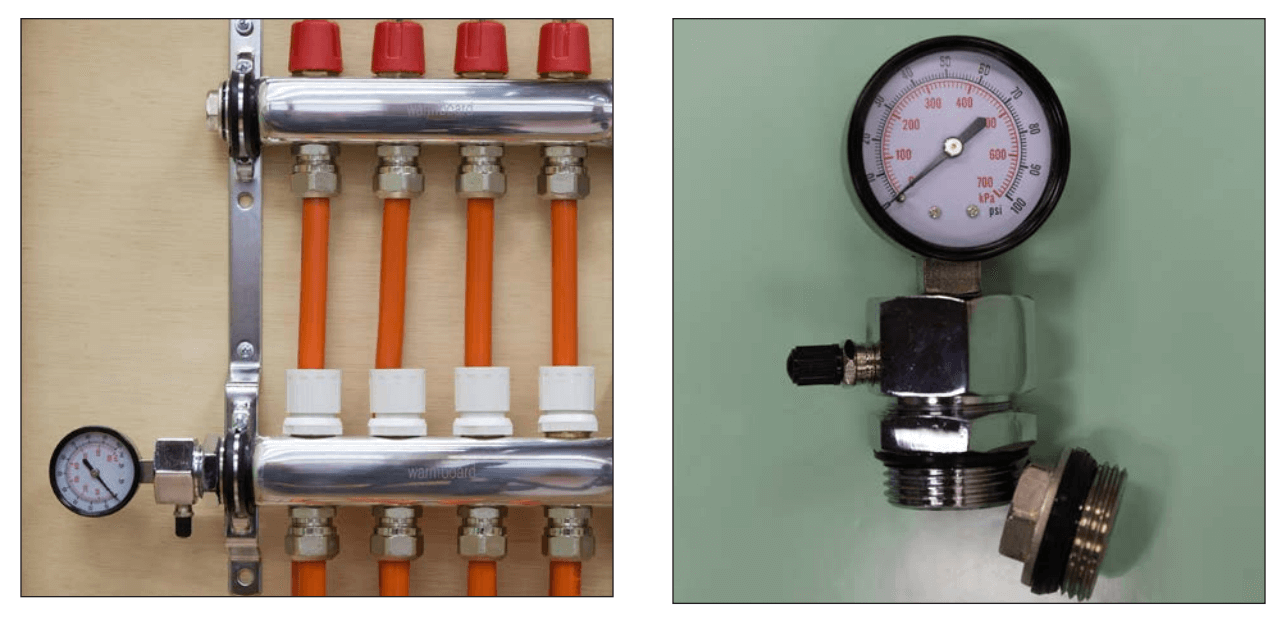

- Remove both 1″ ball valves on both manifolds to expose the 1″ BSPP fittings

- Close the caps on the air vents

- Replace with pressure test kit and end cap and fasten securely

- Ensure the supplied rubber “O Ring” is installed properly – DO NOT use tape or pipe dope

- Air test to the mechanical code requirement of 100 PSI for 15 minutes

- After 15 minutes, keep the tubing and manifolds under pressure with 60 PSI of air during the construction process. NOTE: 5–10% of the air will settle and cause the PSI to drop

- Do NOT leave tubing exposed and pressurized during winter months. Water will freeze and expand when ambient air temperatures drop below 35˚F, causing the tubing to burst.

Filling and Purging

The entire closed loop system should be filled with city or well water, and the air needs to be removed from each loop and then entire system. If air is not properly removed from each loop, the system will be noisy and could experience air locks which halts water circulation.

- Use a standard hose (fill hose), and thread on to the supply hose bib located below the manifold air vent

- Thread another standard hose (discharge hose), on the hose bib located below the other air vent. Make sure the other end of this hose is outside the home so water can drain properly

- Open the large blue and red ball valves located next to the temperature gauges. This will allow the water to circulate from the supply and return distribution lines

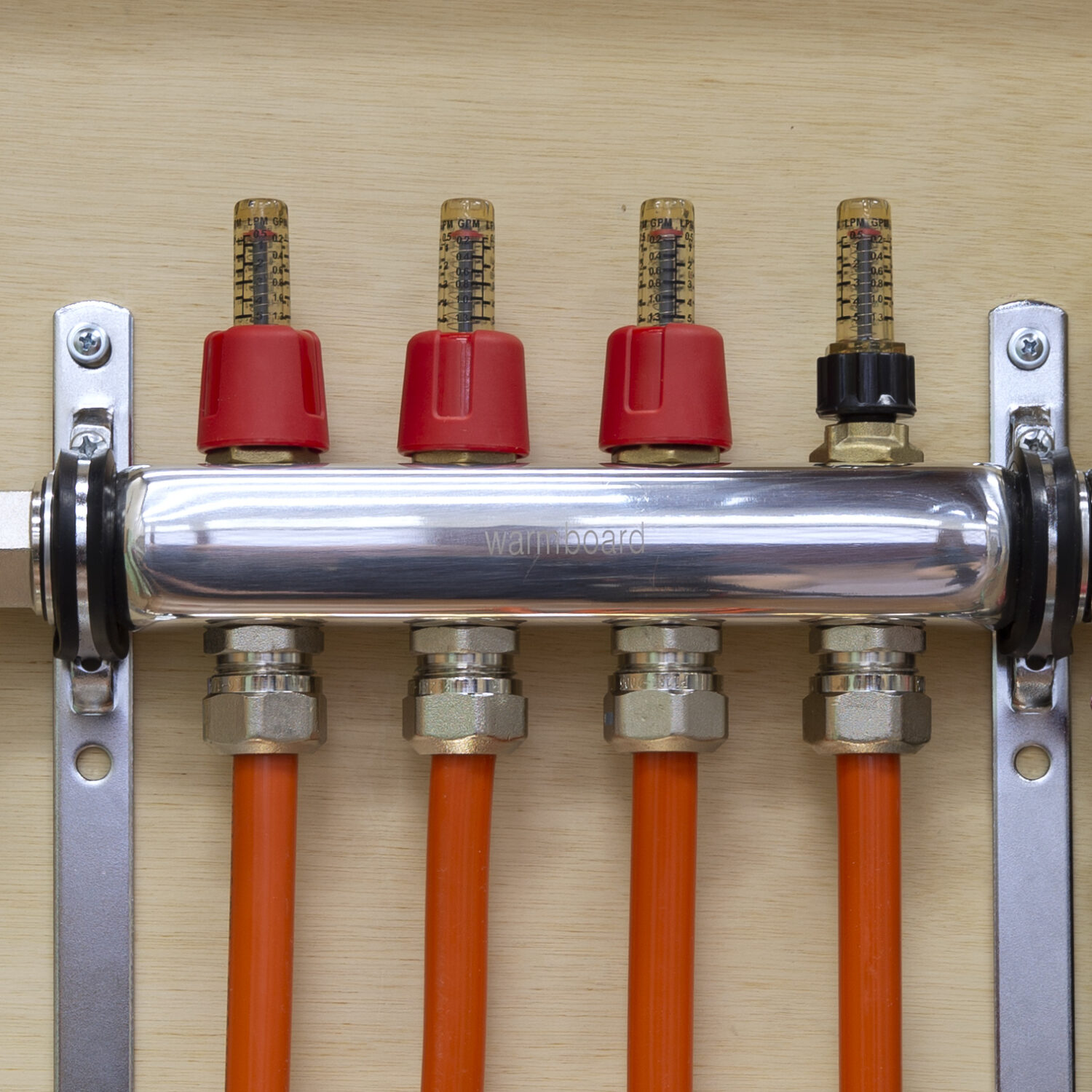

- Remove all red plastic flow meter covers on the supply manifold to access the balance valve flow adjustment for each loop

- Turn the black knob located below each sight glass clockwise until the balance valve is completely closed and no water can flow through

- With all balance valves closed, turn the spigot on and circulate water through the manifolds.

- Keep the water running until all air has been discharged from both hoses and the manifolds. When complete, turn off the ball valves located below the air vents

- Turn a black knob (counterclockwise) on only one loop to the fully open position to adjust flow

- Continue filling and flushing this loop with water by opening the ball valves and witnessing air burping from the discharge hose. After several minutes, no more air will discharge and you can shut off the ball valves located below air vents

- Continue this process for each loop to purge all air

*A different hose bib is provided than the one shown in this image:

- If installing Warmboard Comfort System, refer to the WCS Installation Guide to complete the steps shown on this page.

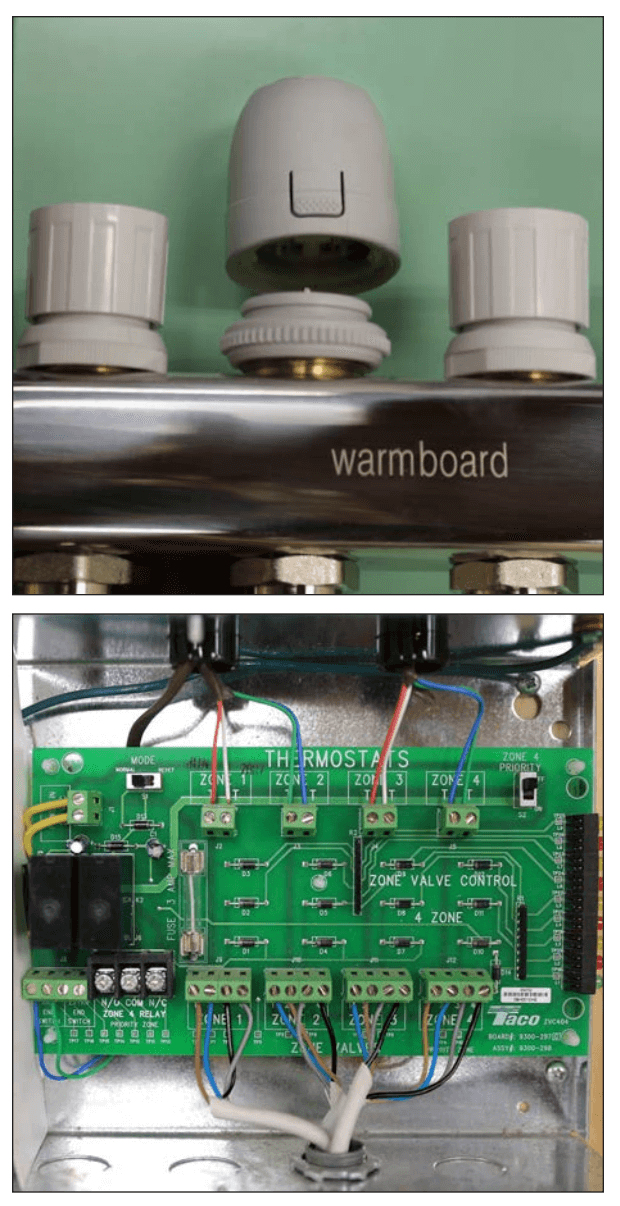

Actuators

Actuators are used in applications where two or more thermostats will be used to open and close specific loops on a manifold. The term used for this feature is

“multi-zone manifold”.

The normal position of the actuator and the manifold valve is closed. When the thermostat calls for heat, it slowly melts the wax motor in the actuator and

opens the valve on the manifold allowing hot water to pass.

Actuator Installation

- Remove the white plastic manifold valve shut off from the return manifold

- Thread on the separate plastic actuator tailpiece that was packaged with the actuator

- Proceeding with the 4 wire heat motor actuator, firmly press on the finger tab located on the actuator to release the locking mechanism, and snap it onto the actuator tail piece. When correctly attached, the manifold valve will be completely closed

- Press the finger tab and pull upward to remove the actuator

- If installing Warmboard Comfort System, refer to the WCS Install Guide to complete the steps shown on this page.

- We recommend Taco Zone Valve Controls to wire the thermostats and actuators. Visit bit.ly/2yAfMd2

- We provide four wire actuators; the blue and brown wires control the motor (terminals 1 and 2), the black and grey wires control the end switch (terminals 3 and 4).

- Actuators are “closed” when there is no call for heat. Power up the actuators in the “open” position before threading on to the manifold.