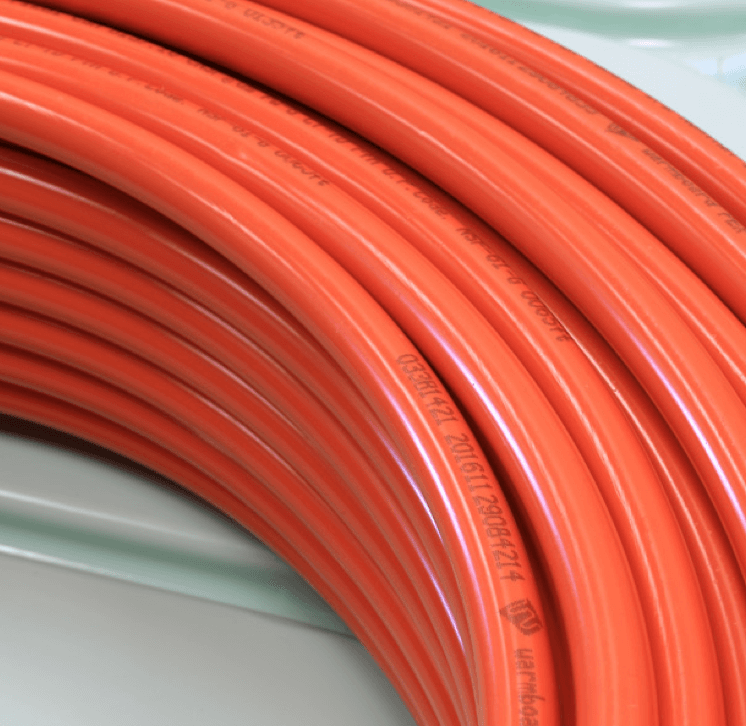

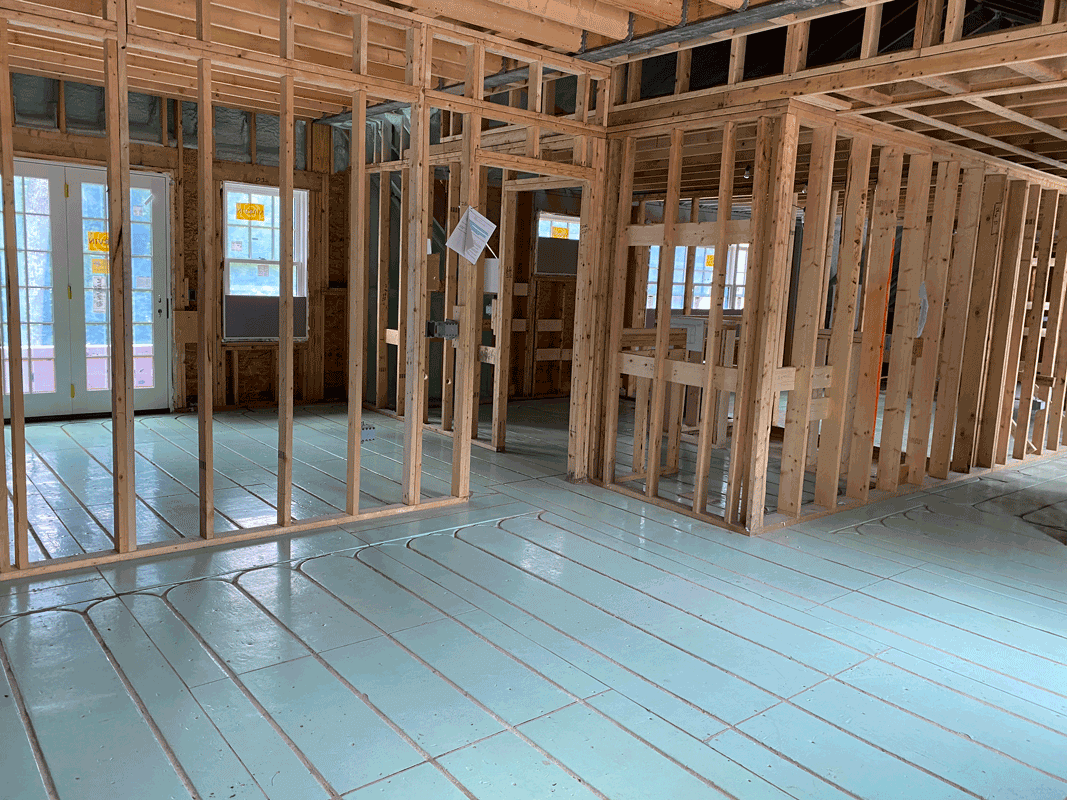

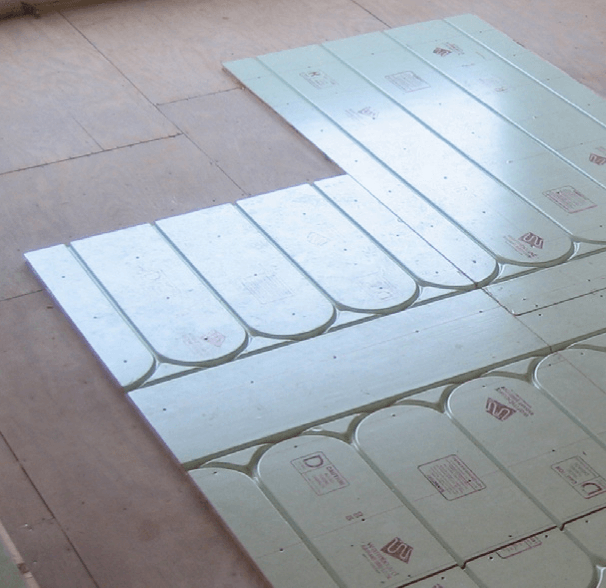

Warmboard-S is a structural, tongue and groove hydronic radiant subfloor panel made from 7-ply plywood with a conductive .025″ thick 1070 aluminum alloy skin bonded to the entire top surface. Each panel type is stamped with a series of aluminum channels on the top surface to accommodate the installation of 1/2″ PEX or PEX-AL-PEX tubing.

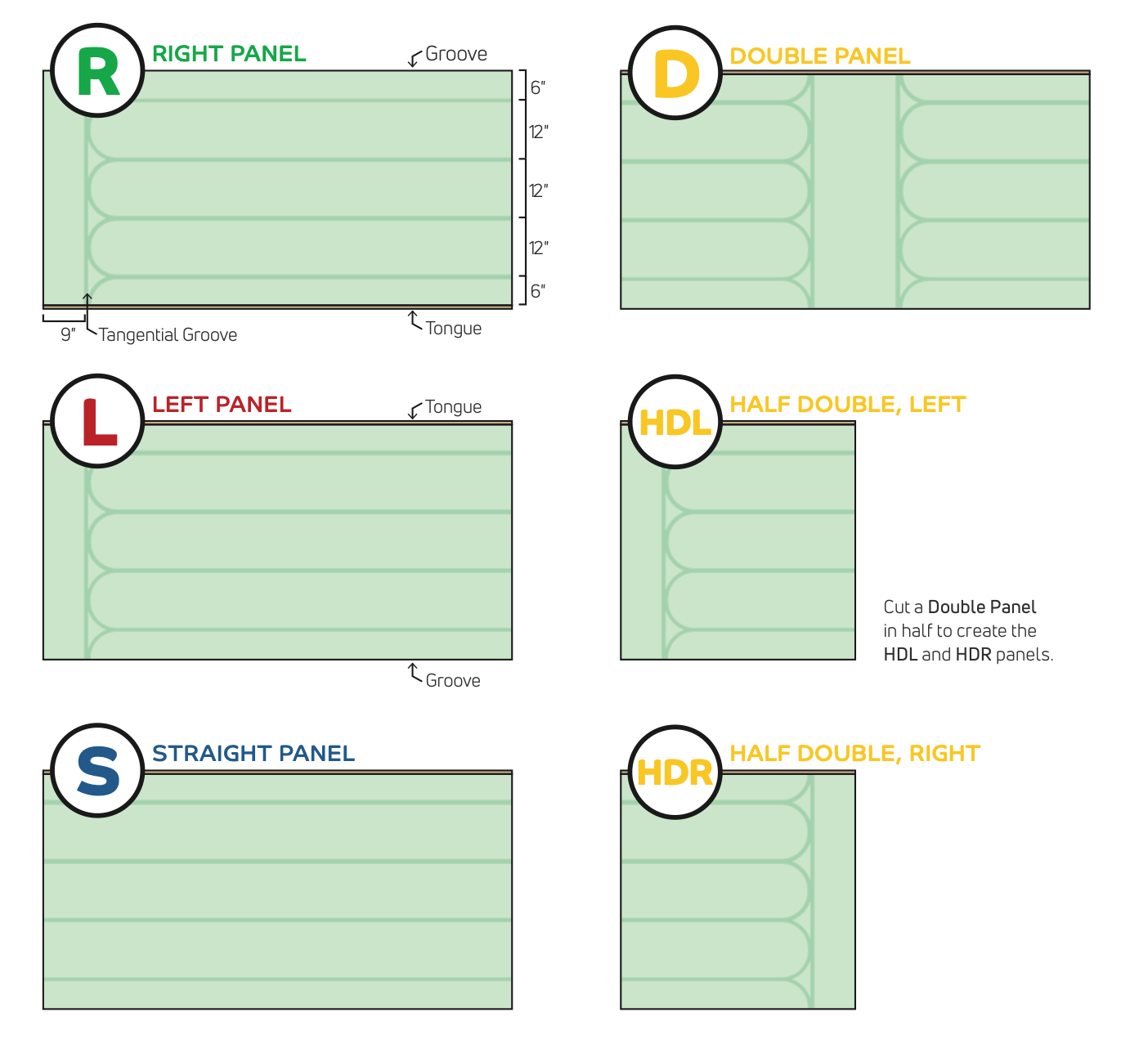

Warmboard-S consists of four, modular panel types, each measuring 4′ x 8′ x 1 1/8″ thick and weighing approximately 100 lbs. In a completed assembly, Warmboard-S weighs 3.2lbs per square foot, which includes the panel, tubing and water.

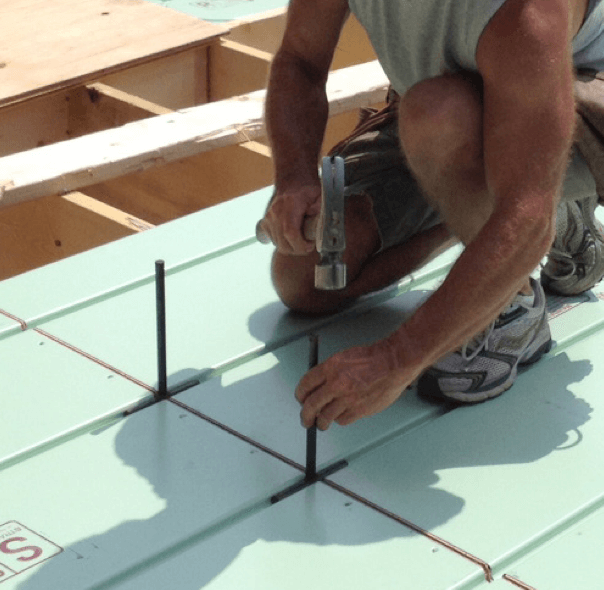

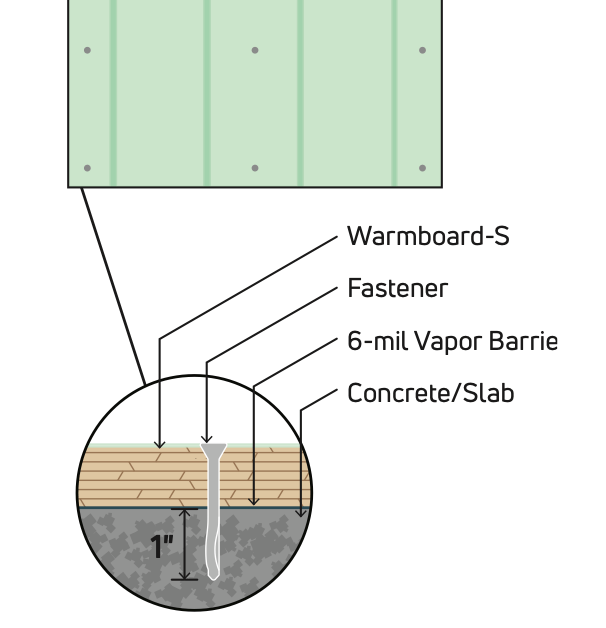

Warmboard-S is typically installed over joist (24″ OC maximum), though also over concrete or subfloor.

Non-aluminum filler panels are also available.