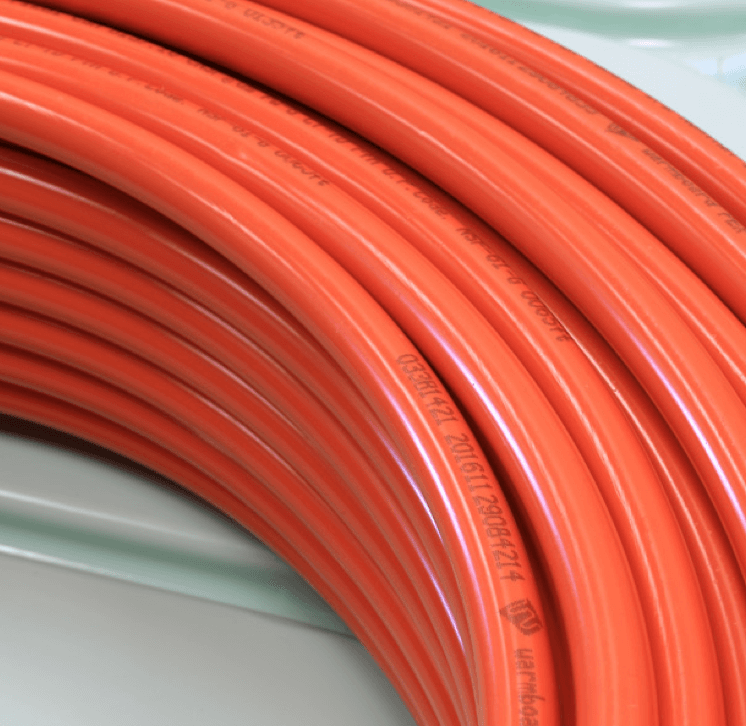

Warmboard-R is a hydronic radiant panel made from oriented strand board (OSB) with a conductive .025″ thick 1070 aluminum alloy skin bonded to the entire top surface. Each panel type is stamped with a series of aluminum channels on the top surface to hold 1/2″ PEX or PEX-AL-PEX tubing.

Warmboard-R consists of two panel types which weigh approximately 25 pounds, are 13/16″ thick and measure 23 7/8″ x 48″. In a completed assembly, Warmboard-R weighs 3.2lbs per square foot, which includes the panel, tubing and water.

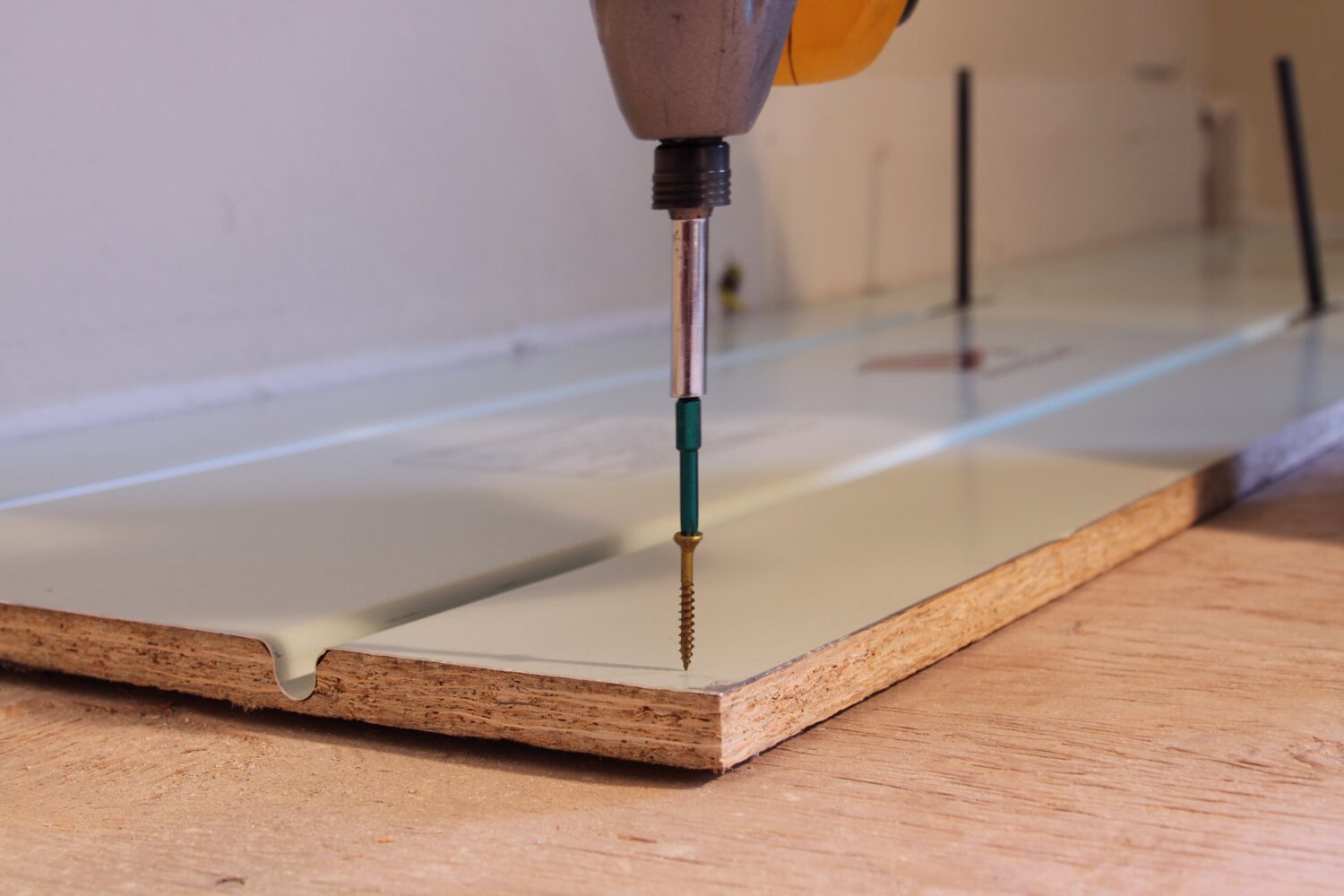

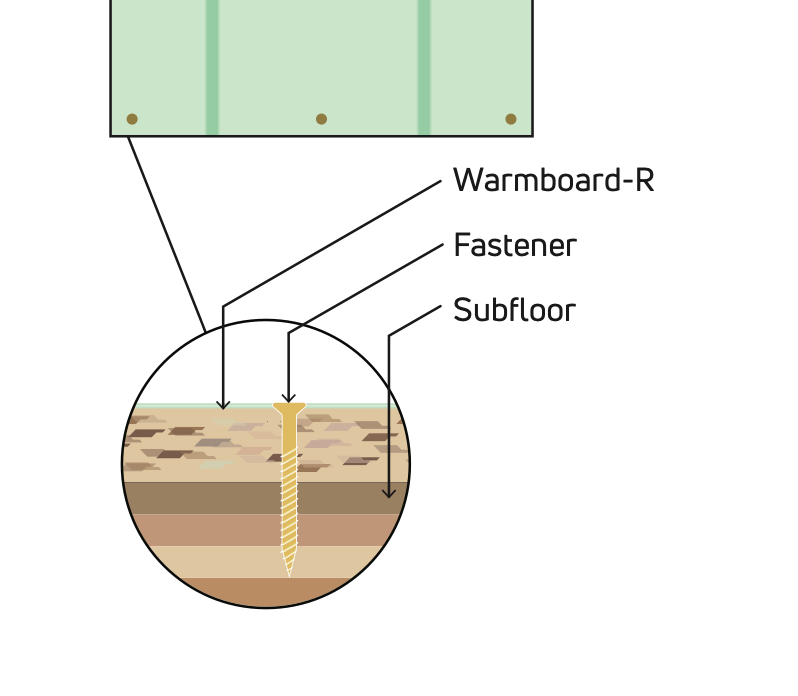

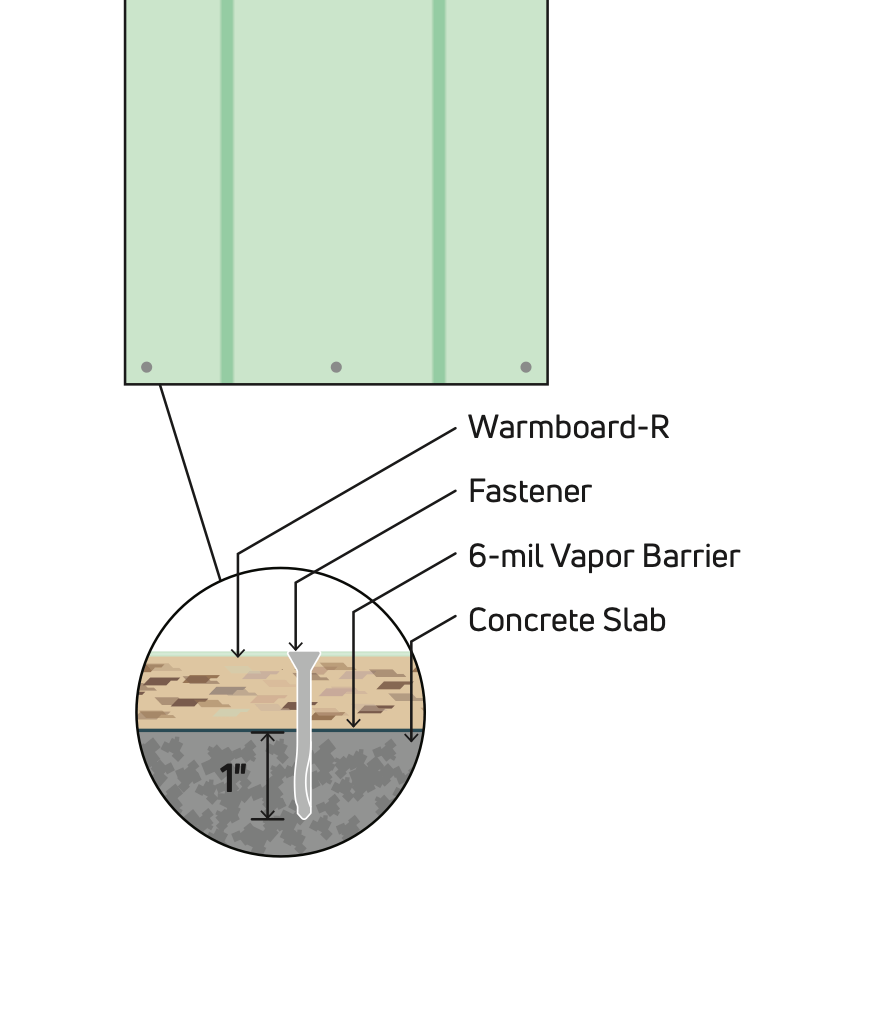

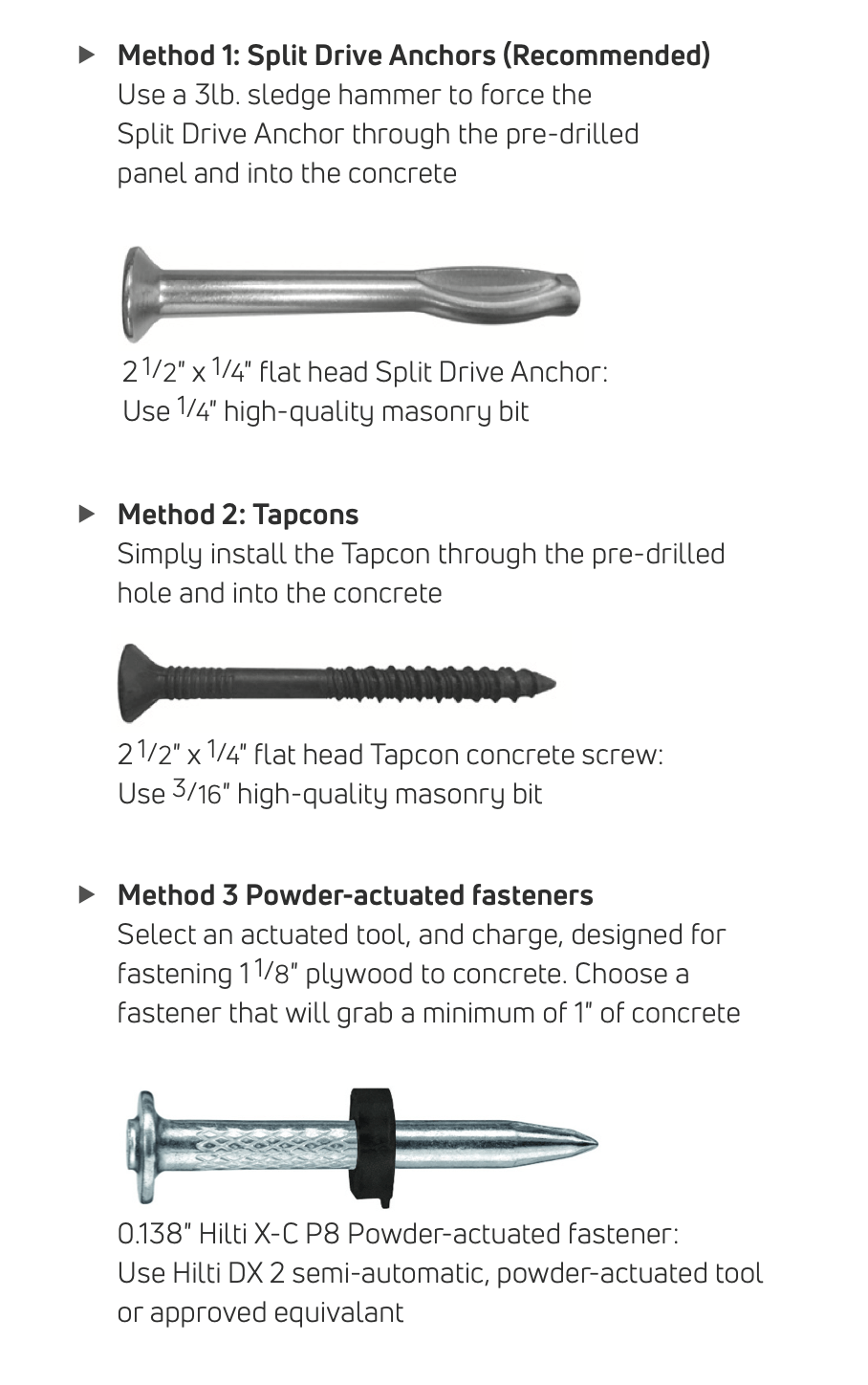

Warmboard-R is typically installed over concrete or subfloor, though is also used in walls and ceilings. Non-aluminum filler panels are also available.

![]()