Slab heating systems Limitations

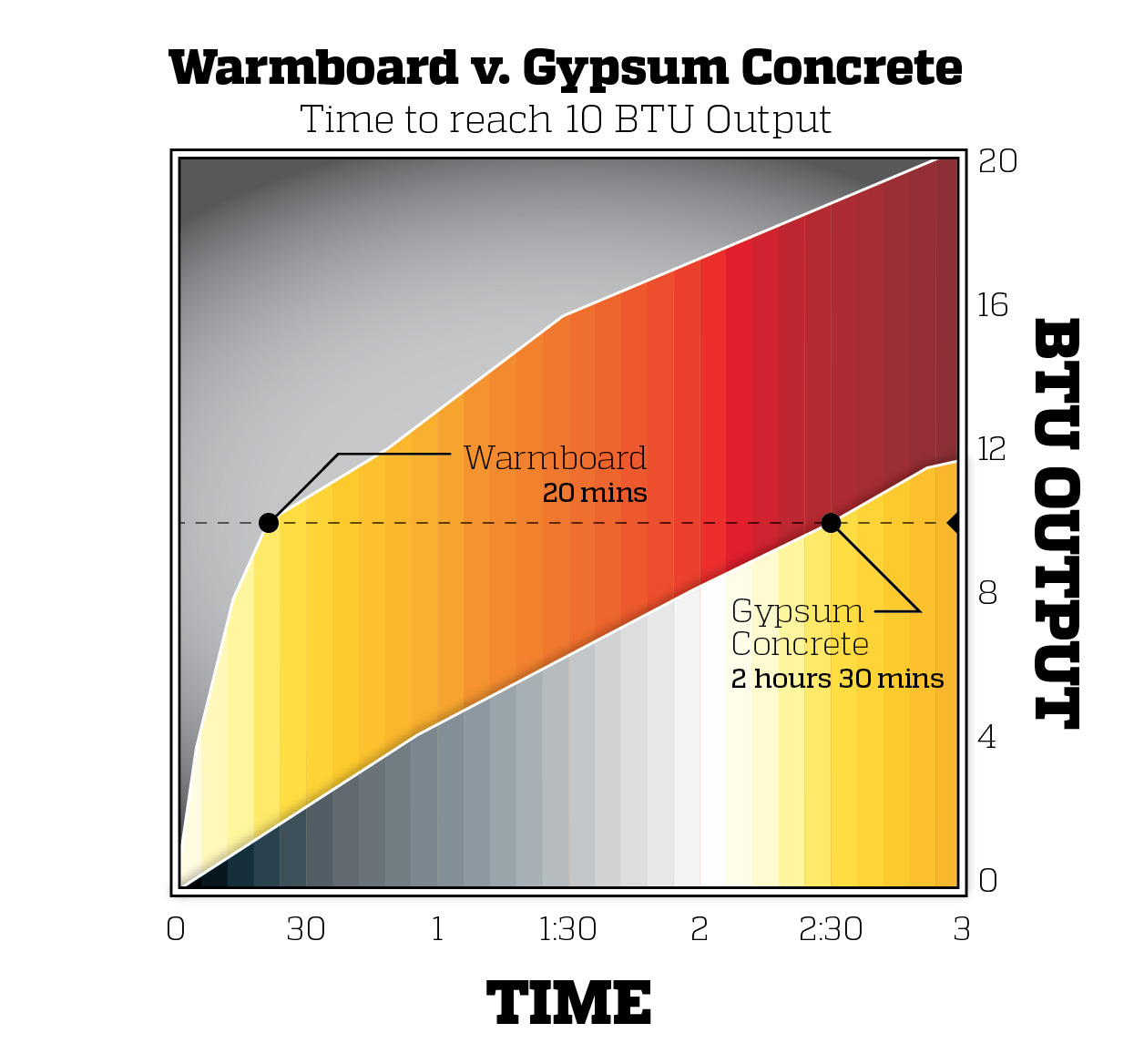

In the past, radiant heat had a good reputation for comfort once the floor reached the correct temperature. But the high mass systems which were common in the 1950’s took many hours (or days) to reach the correct temperature. Given a blank sheet of paper, no engineer familiar with the laws of thermodynamics would choose such a material like gypsum concrete for a radiant panel. It is a poor conductor of heat and its high mass makes it difficult to accurately control in order to meet the changing needs of a home. Slab-based radiant has other restrictions as well:

![]()

• They require additional construction costs to support their weight

• They make it difficult to install hardwood and other finish floor materials

• Unyielding, rigidly hard slabs are uncomfortable to stand or walk on

• They bring moisture into your home, increasing the risk of mold

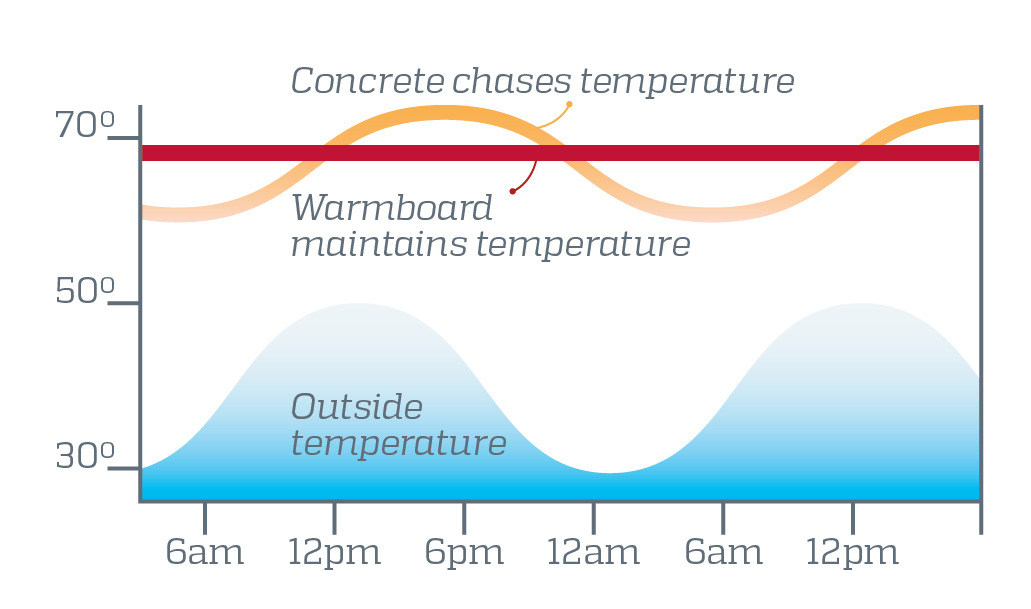

All homes have their heat loads change throughout the day as the sun rises or sets, weather changes, lights or ovens are turned on, guests arrive or leave. Warmboard quickly adjusts to meet those changes. High mass simply can’t keep up. And when you return home from vacation, Warmboard can make your home to the correct temperature in a couple of hours, not a day or more.

Bottom line: Warmboard is the modern choice for radiant because it was engineered to take full advantage of the laws of thermodynamics. Good science ensures your comfort.

Watch this video comparing Gypsum concrete against Warmboard panel performance:

Related blog posts: