The Most Important Comparison is Conductivity![]()

Why Warmboard? Simply put, the job of a radiant panel is to conduct heat from water in a tube to the surface of your floor. Gypsum concrete may have a long association with radiant, but given a blank sheet of paper today, no engineer would choose that material for a radiant panel. It is a poor conductor and its high mass cannot accurately respond to your changing heating needs. Warmboard’s high conductivity and low mass mean:

- Floors are more evenly heated and the system responds more quickly and accurately to satisfy your ever changing heating needs. Both of these performance qualities are essential to your comfort

- The water in those tubes can be much lower in temperature, saving energy and significantly extending the life of all the equipment in your heating system

- Your investment in beautiful hardwood flooring is protected through even floor temperatures, secure fastening and comparably dry material under your hardwood

- Tubing can be more widely spaced, saving on tubing, manifolds, controls and all the labor to install these components in your system

There’s a reason that frying pans are made of thick aluminum and not concrete; conductivity is key when it comes to fast heat.

There’s a reason that frying pans are made of thick aluminum and not concrete; conductivity is key when it comes to fast heat.

Five Times the Conductivity

It’s an undeniable fact that the thick, aluminum plate that covers the entire surface of Warmboard panels is five times more conductive than a typical gypsum concrete slab.

Yes, Warmboard costs a little more, just as all superior products do when compared to inferior ones. But as part of a complete radiant system, that premium is small while the conductivity improvement is substantial! It is rare that a consumer is given an opportunity to choose between similarly priced products, one of which outperforms the other by 500%!

Yes, Warmboard costs a little more, just as all superior products do when compared to inferior ones. But as part of a complete radiant system, that premium is small while the conductivity improvement is substantial! It is rare that a consumer is given an opportunity to choose between similarly priced products, one of which outperforms the other by 500%!

Does Not Apply:

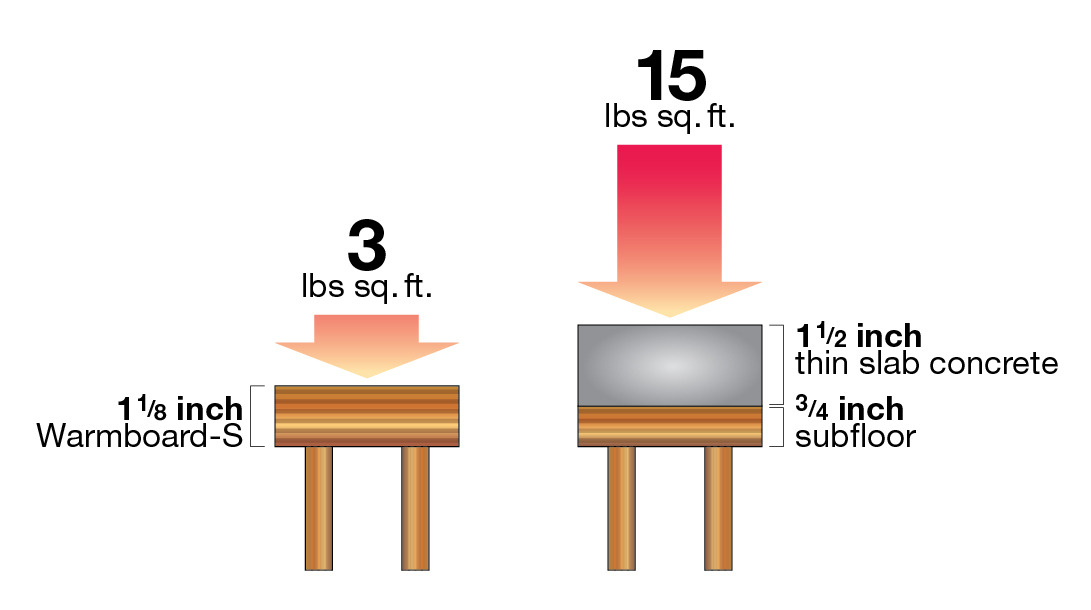

The following list of considerations applies to a gypsum-based radiant system, but not Warmboard-S.

- Additional subfloor installation

- Increased amount of tubing, manifolds, controls and the labor to install them all

- Sealant to protect porous gypsum concrete from damage

- Addition of pressure treated bottom plate for all walls

- Upsized floor joists for increased weight

- Addition of nailing strips or floating plywood overlay in order to achieve nailed in place hardwood flooring

- Vacation home may require remote communication system to heat home a day or more prior to your arrival

- Higher water temperatures: 110–150ºF (43–65ºC) compared to 80–120ºF (26-49ºC) with Warmboard-S

Performance You Can See

Performance You Can See

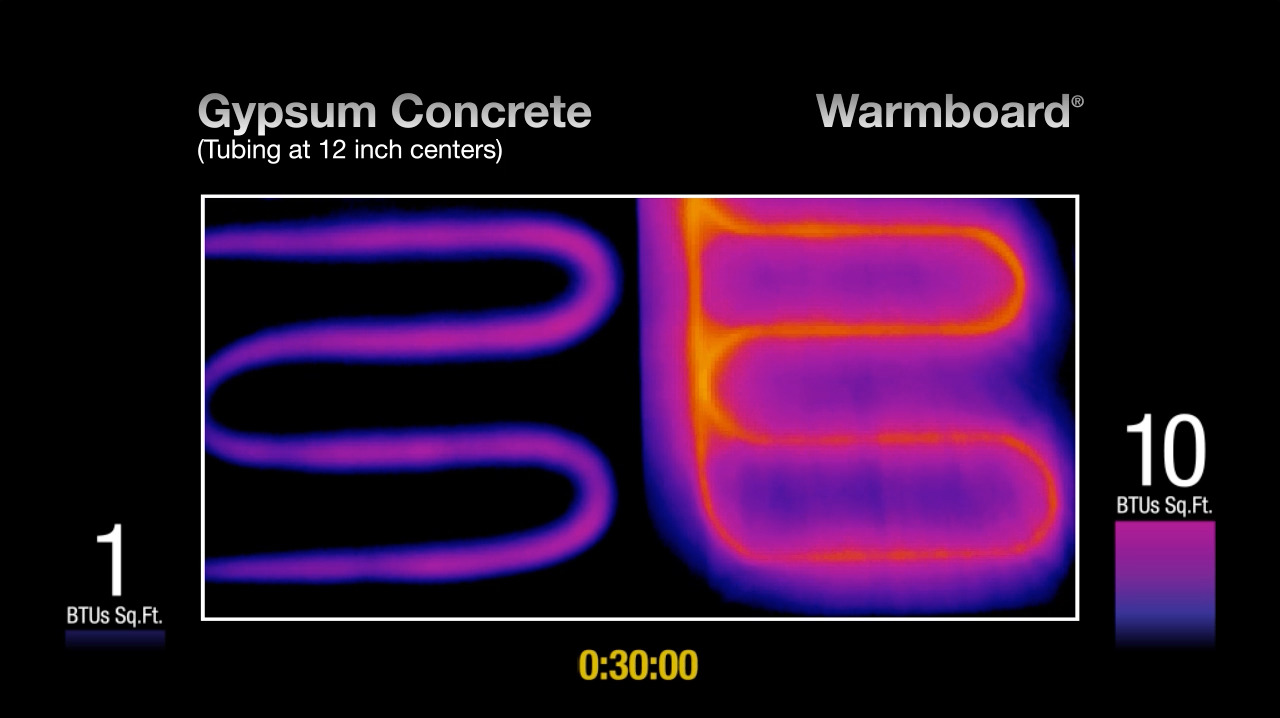

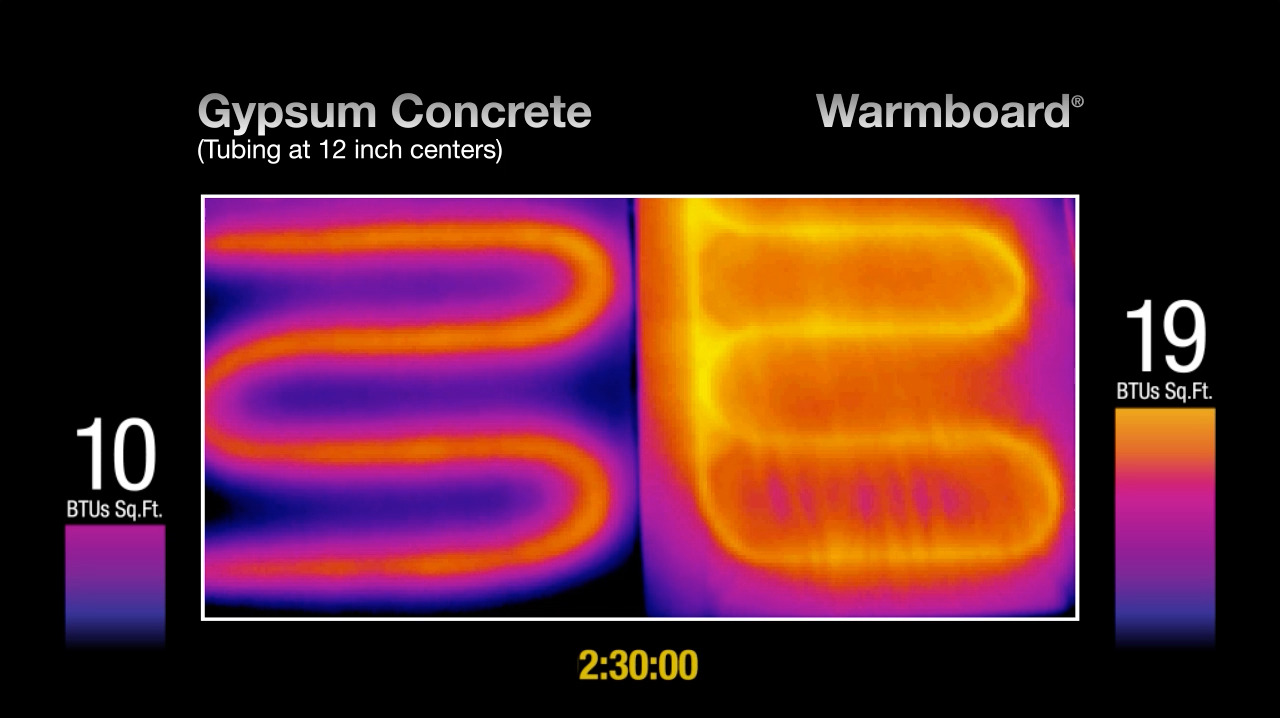

Forget the claims, witness the truth. These thermographic images capture the stark difference between Warmboard and a traditional gypsum slab in action. Both panels faced identical air and water temperatures, yet the results are unmistakable.

These thermographic images (below) will help you better understand the very real and significant differences in performance between a gypsum slab and Warmboard. The panels in this study were tested side-by-side with identical air temperatures, water temperatures and floor coverings. The differences are obvious. Higher output, more even floor surface temperatures and much, much faster response, make a powerful case for high conductivity, low mass Warmboard.

After 30 minutes, the gypsum concrete is only producing 1 BTU/sf, while Warmboard is already producing 10 BTUs/sf.

After 30 minutes, the gypsum concrete is only producing 1 BTU/sf, while Warmboard is already producing 10 BTUs/sf.

After 2 hours, 30 minutes, gypsum concrete is producing 10 BTUs/sf, while Warmboard is producing 19 BTUs/sf, with more even heat.

Check the full video showing Warmboard’s aluminum plate conducting heat 5x faster than gypsum concrete:

See more related content: