While we insulate homes to prevent heat from escaping outside, even the most well-insulated homes experience heat loss. This is because heat can be transferred through conduction, convection, and radiation. Conduction is the transfer of heat from one molecule to another through direct contact. Convection is the transfer of heat through the movement of fluids or gases. Radiation is the transfer of heat through electromagnetic waves.

Hydronic radiant heating systems work by transferring heat to the interior space through radiation. The water in the tubing heats the panel, which then radiates across the surface of the floor and heats the objects in the house (flooring, furniture, people, etc…). To maximize energy efficiency, walls should have a low level of conductivity (well insulated) and radiant panels should have a very high level.

However, not all radiant heat systems use the same materials, thickness, or water temperatures. This means that the heat flow rate of a radiant heating system can vary throughout the day.

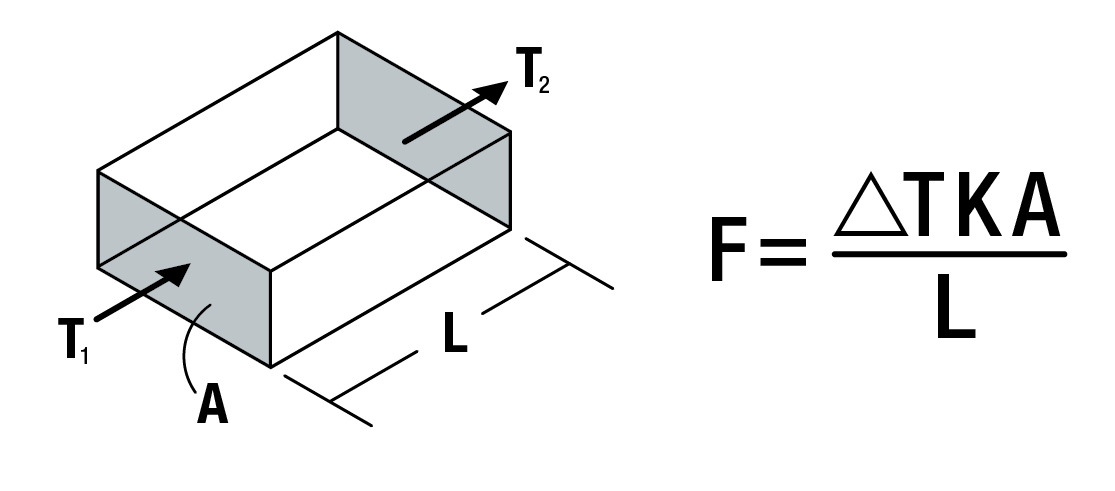

Here is a simplified equation for calculating heat flow through a radiant panel:

![]()

The rate at which heat flows through a radiant panel is determined by the following factors:

- The difference in temperature between the inside of the home and the water in the radiant tubing (called the Delta T [ΔT]).

- The cross-sectional area (A) or thickness of the panel.

- The coefficient of conductivity (K) of the panel material.

- The distance the heat must travel to reach the midpoint between two tubes (L).

To maximize energy efficiency, it is important to choose a radiant panel material with a high coefficient of conductivity and to install the panels close together. This will minimize the distance the heat must travel and maximize the heat flow rate.

There is an equation that predicts heat flow through any material, whether it is a wall or a radiant panel.

Low Water Temperatures with High Conductivity materials

By doubling the difference in temperature (rT), between the water in the tubing and the air inside of your home, we can double the heat flow. We can also double the thickness (A) of a radiant panel or double the conductivity (K) of a panel material and we double the heat flow.

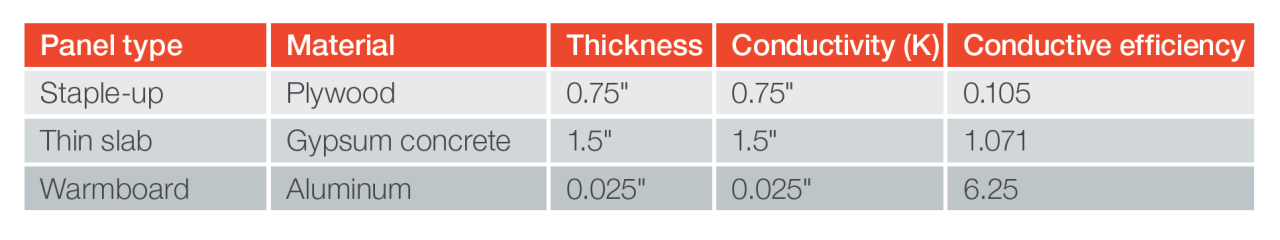

The table shows that aluminum has the highest conductivity of the materials listed, followed by plywood, and gypsum concrete. This means that aluminum panels would be most efficient at transferring heat to the room. Warmboard radiant heated panels are made with aluminum of 0.025″ thickness.

Warmboard vs Thin Slab and Staple-Up

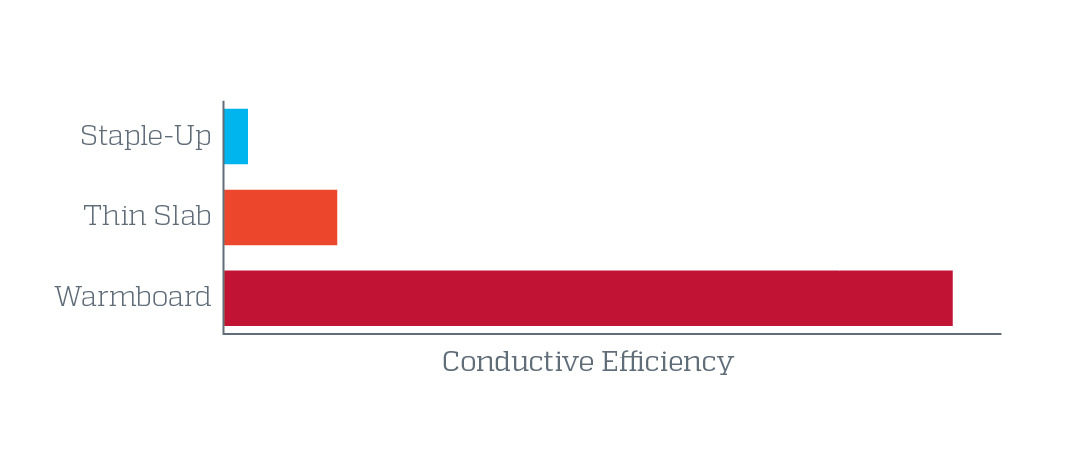

The graph below assumes that we hold tubing spacing (L) and water to air temperature difference (rT) constant. With these values held constant we multiply thickness (A) by the conductivity (K) to find the relative conductive efficiency of common panels used in framed floor construction.

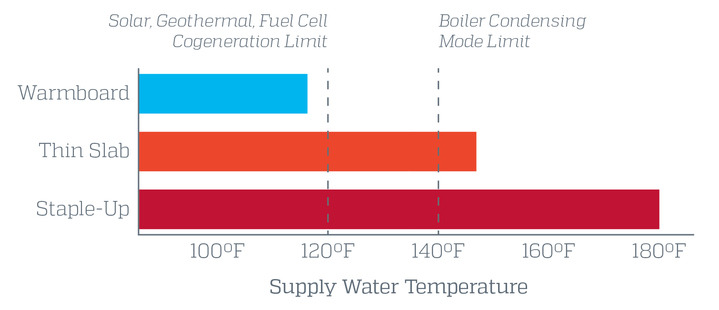

These bars show the huge difference in heat flow between these panel types. It becomes obvious why thick aluminum is so essential for high performance. Of course for a given home, all panel types need the same heat flow in order to overcome the same heat loss. So in order to ensure that the more efficient panels do not overheat the home, you can lower the water temperature until the heat flow is held constant for all three panels.

This brings us to the second graph. Here we took long accepted lab testing of various panels. We assumed that all panels had a floor covering with a resistance of R-2 (common for carpeting) and that we had a heat loss of 20 BTU h/sf (common for modern construction). The Warmboard and gypsum panels assumed 12″ on center tubing but the staple-up assumed 8″ because that was the only testing available. Interestingly enough, even with 50% more tubing, the Staple-Up was running at the maximum temperature 180°F (82ºC) allowed for radiant tubing. Gypsum systems run much lower, about 145°F (63ºC), but still above the threshold for condensing boiler optimization.

Warmboard runs at a modest 115°F (46ºC), which maximizes the efficiency of condensing boilers or water heaters. These low water temperatures open up the possibility of using the most energy efficient new technologies such as geothermal, solar and fuel cell cogeneration. We offer solutions for both new construction and remodeling projects. Our team of experts will work with you to recommend the best options for your home, and our products are easy to install. Submit your floor plans to get a free preliminary design here.