For over 20 years, Warmboard has been the trusted name in hydronic floor heating. We’ve helped thousands of clients across the country, from skyscrapers in New York to cozy cabins in Colorado, bring the warmth of radiant heat to over 40 million square feet.

Whether you’re tackling a major project or a small addition, our deep expertise is here to guide you. With every project we offer:

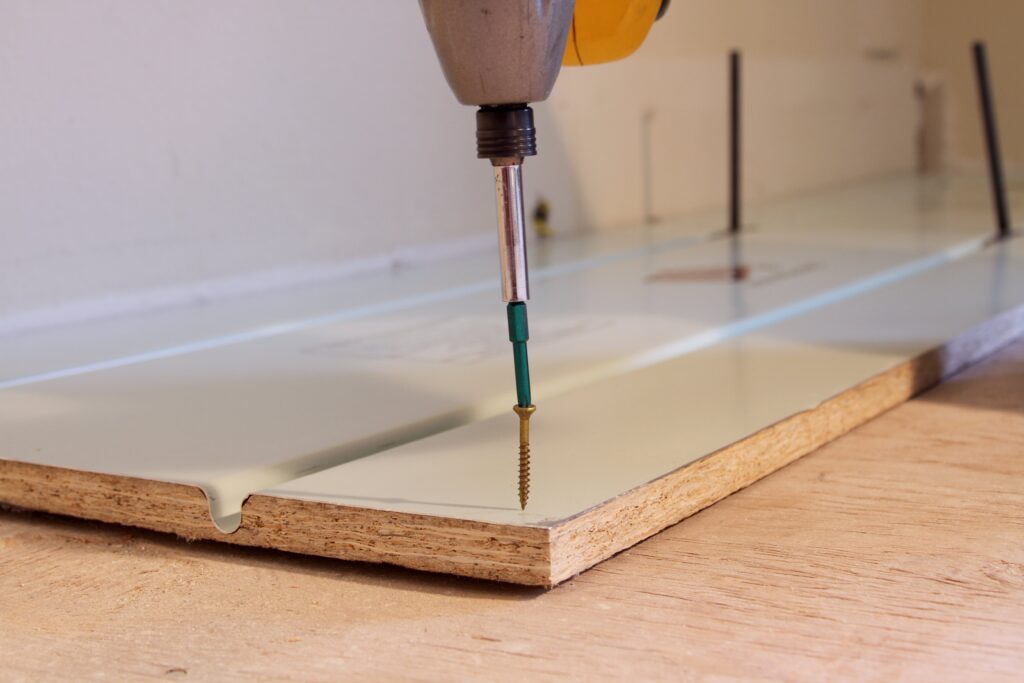

- Detailed installation guides and technical support

- Product recommendations tailored to your project

- Troubleshooting assistance for any challenge