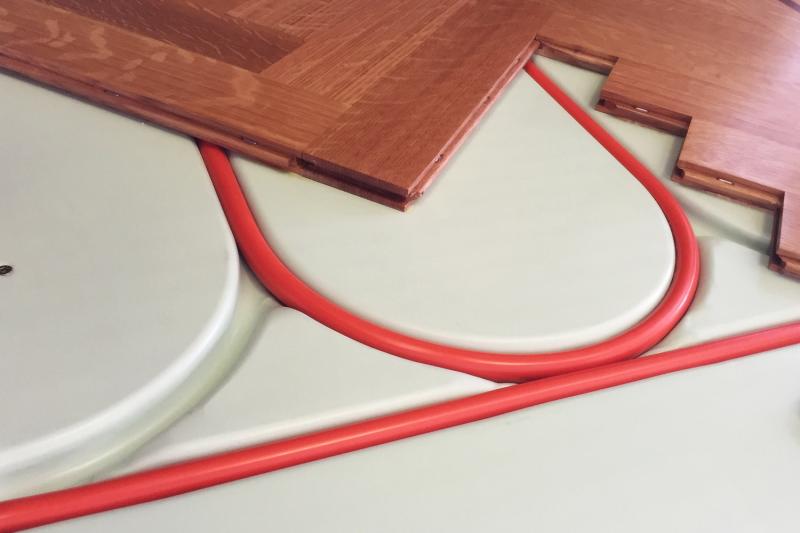

Solid, sawn, hardwood planks have been an integral part of residential architecture for over 400 years. Since 1998, over 40 million square feet has been successfully installed over Warmboard. The long documented history of hardwood combined with our decades of experience tells us that traditional 3/4″ solid plank flooring is the gold standard and accordingly, that is our strong recommendation.

All wood products expand and contract with changes in humidity. Solid plank wood is naturally monolithic and expands and contracts most evenly. When these dimensional changes do occur, cupping, crowning and gapping at the edges may result. These changes are inherent to all wood flooring, regardless of the heating method. To minimize such dimensional changes, especially as humidity varies throughout the seasons, we also recommend quartersawn and/or rift cut planks due to their stability.

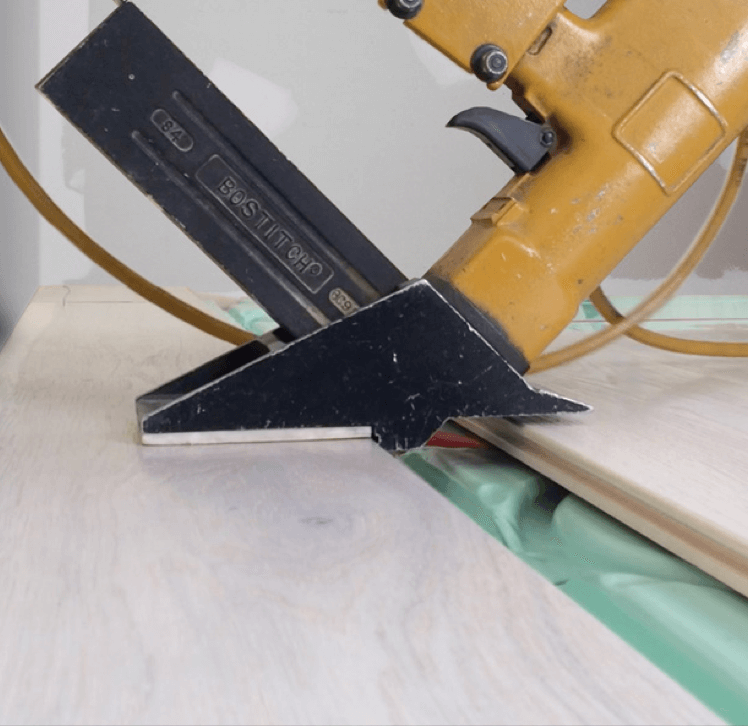

To further limit dimensional movement, ensure the hardwood has the proper moisture content at the time of installation. A good hardwood installer will know the ideal range for your geographic region (moisture content should be at the low end of this range). A moisture meter is required to determine when that moisture percentage is achieved.