Tile or stone set to Warmboard panels is subject to all of the tile setting requirements of any ordinary unheated wooden subfloor.

Testing and Approvals

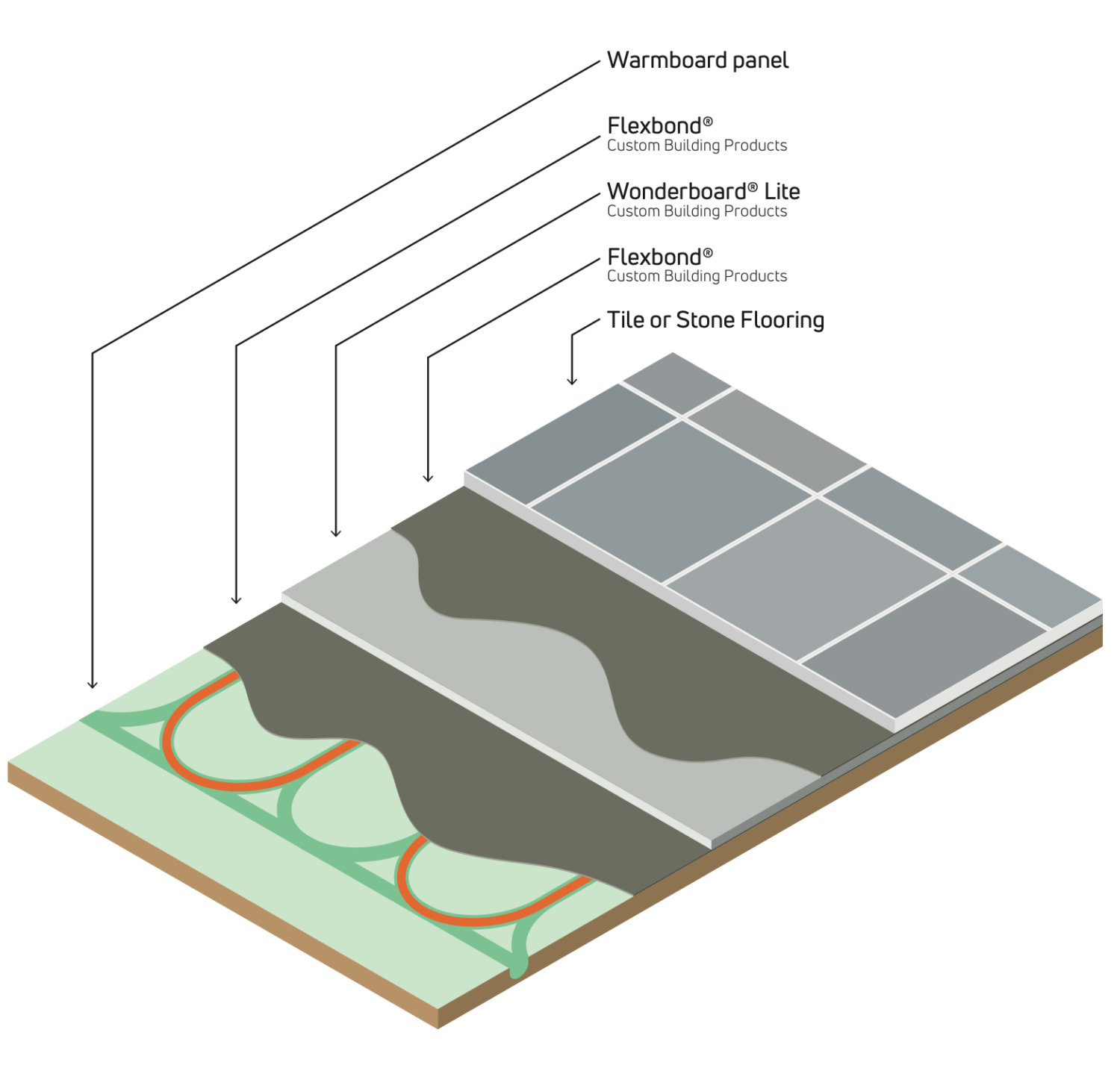

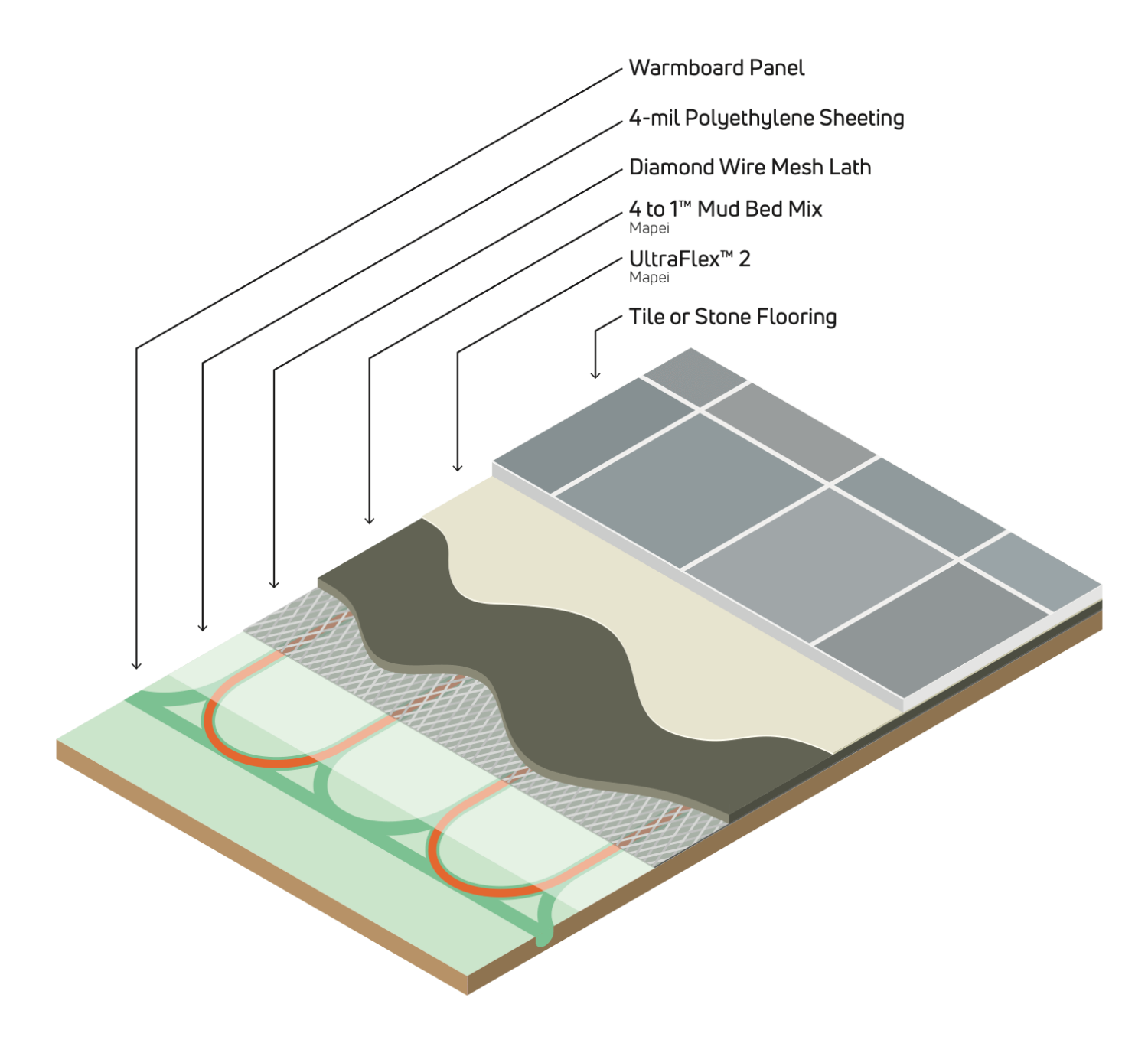

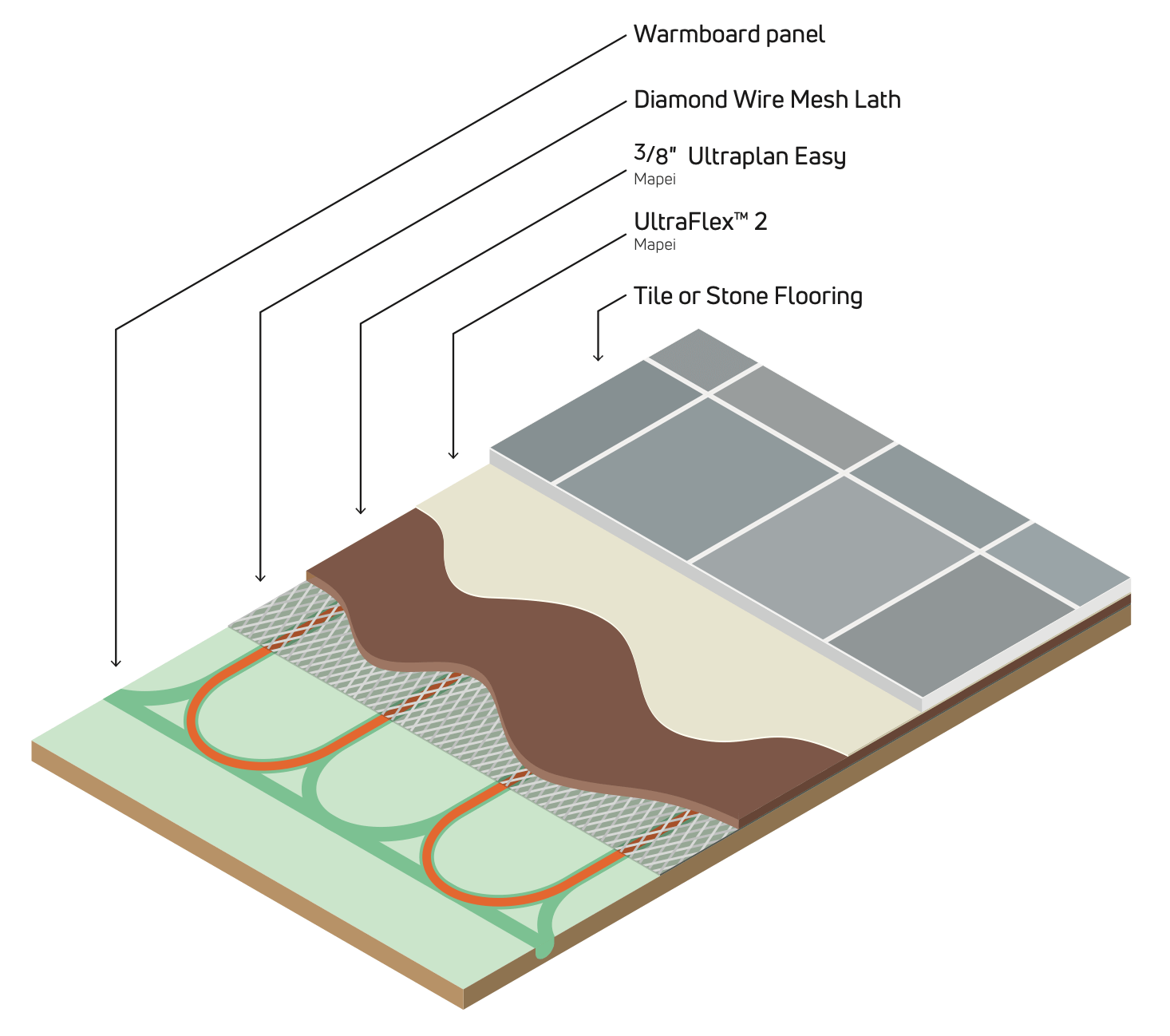

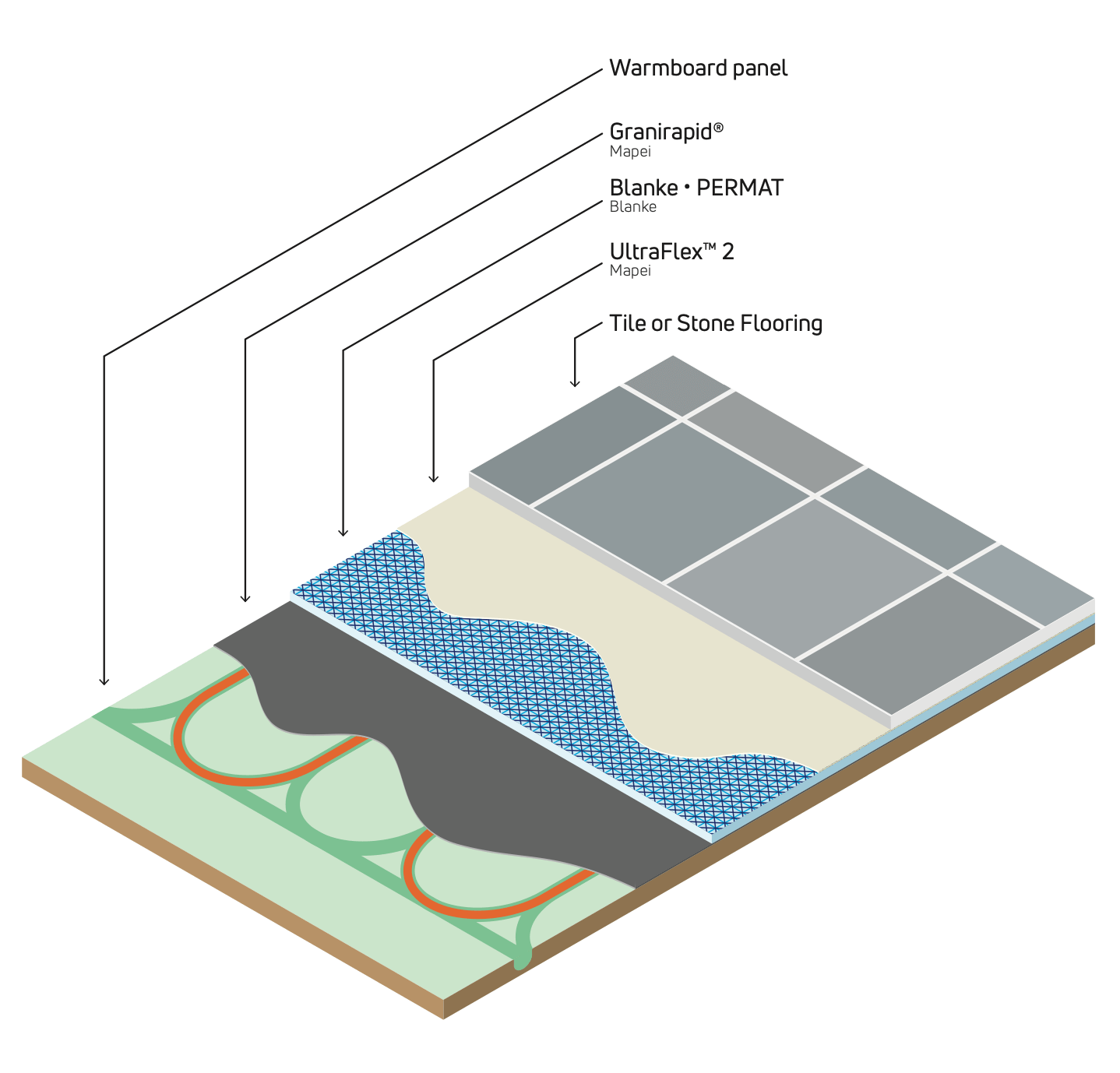

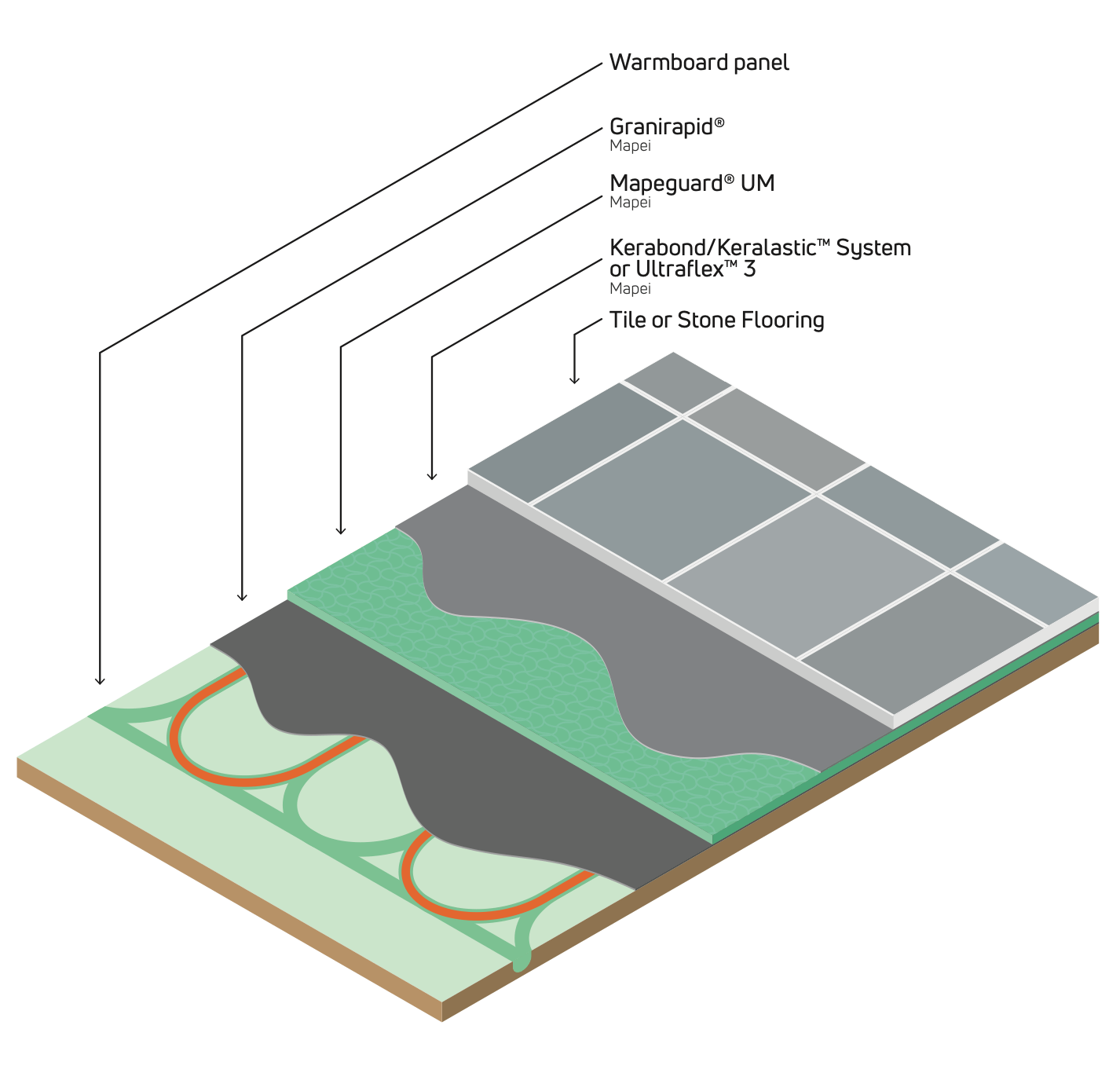

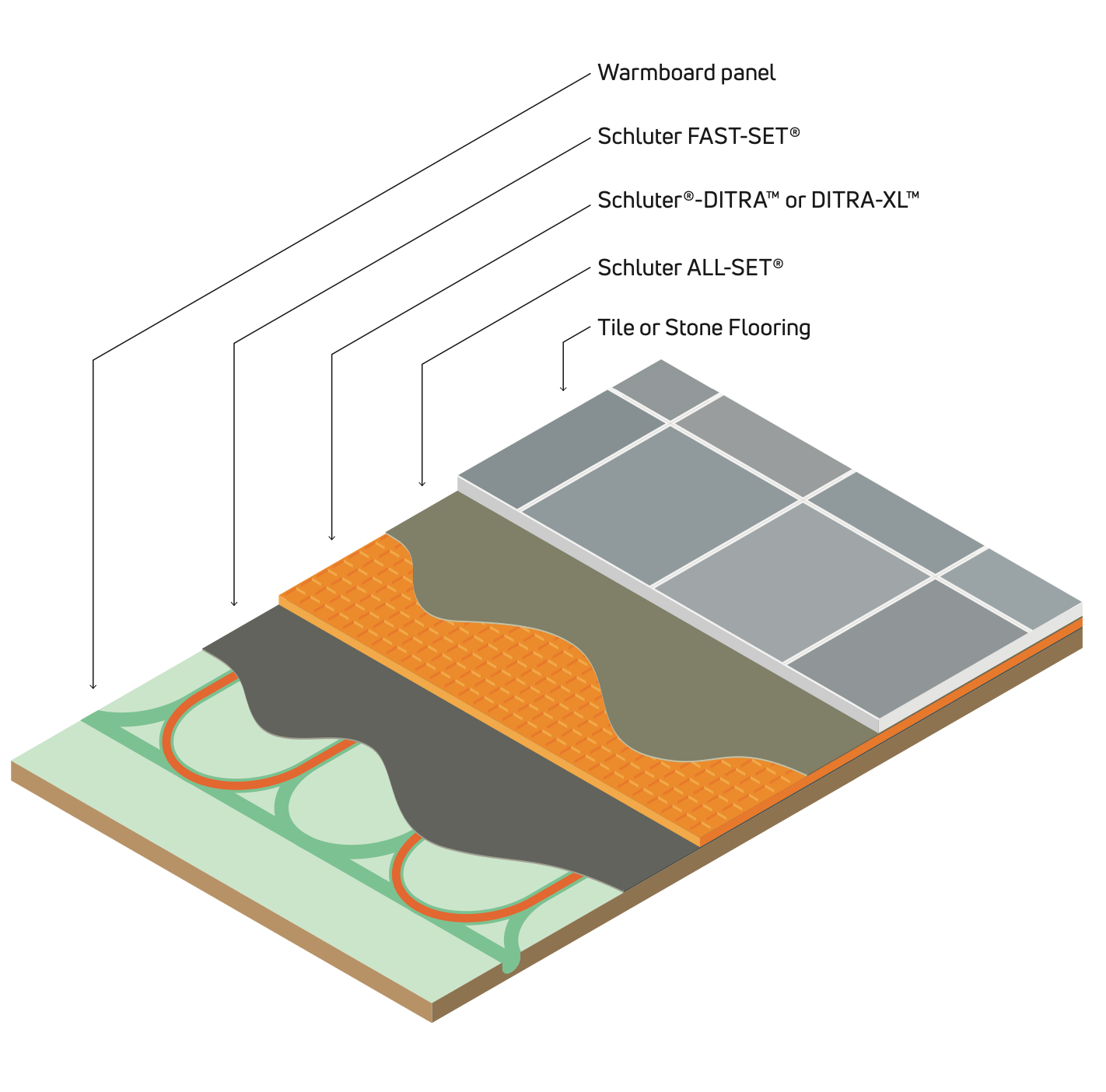

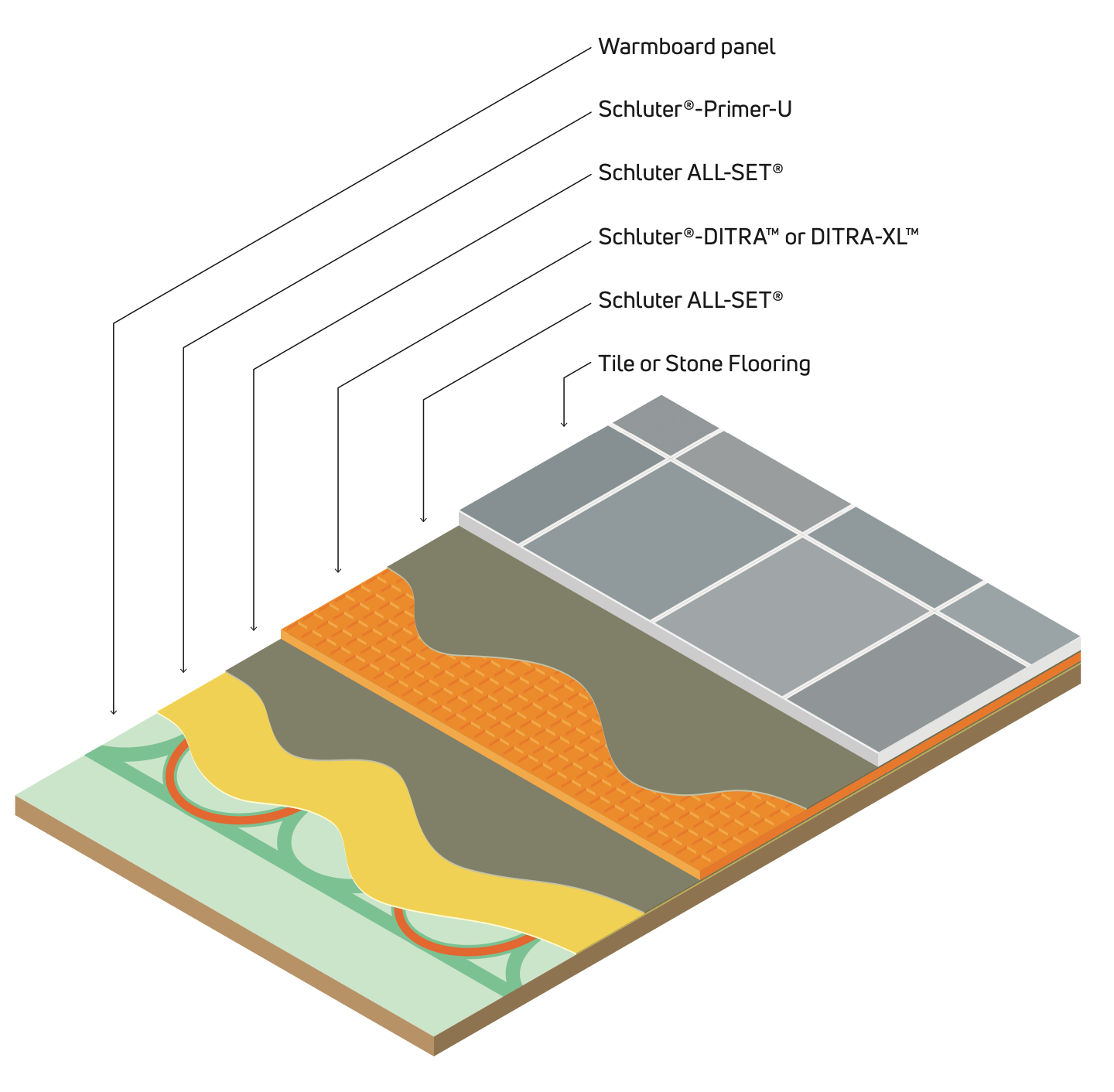

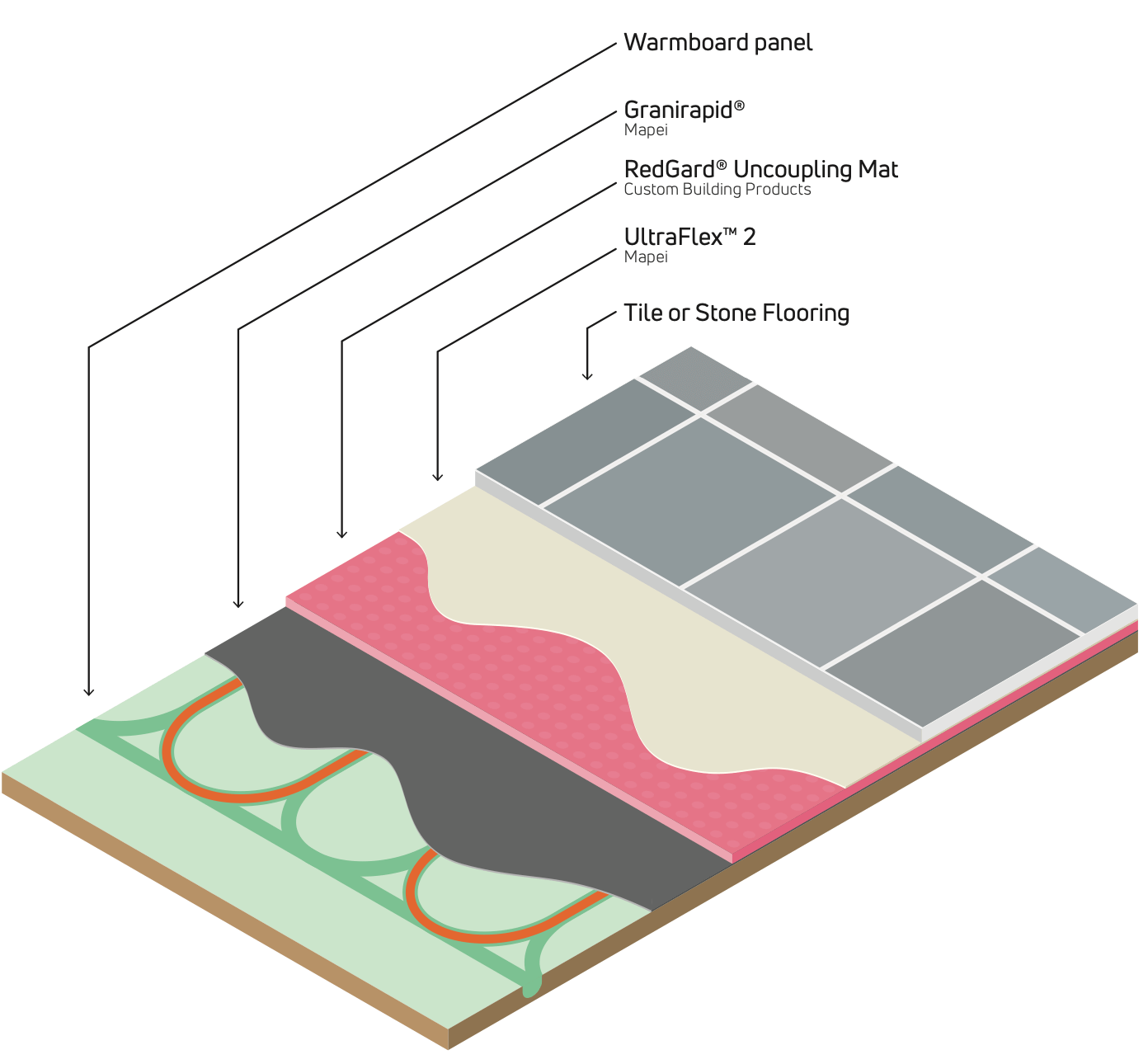

We recommend using one of seven tile assemblies when installing tile or stone over Warmboard. Three of these methods have been warrantied and approved by product manufacturers, and five have been rigorously tested by the Tile Council of America (TCNA). These tests provide an expert third party endorsement for best practices when installing tile and stone over Warmboard radiant panels.

Robinson Floor Test (ASTM C627) results are available upon request.

NOTE: Warmboard-R has not been tested by the TCNA. However, due to the near identical properties of the panel, we are convinced that Warmboard-R would perform equally under the testing conditions. Our experience in the field supports this.